Overview

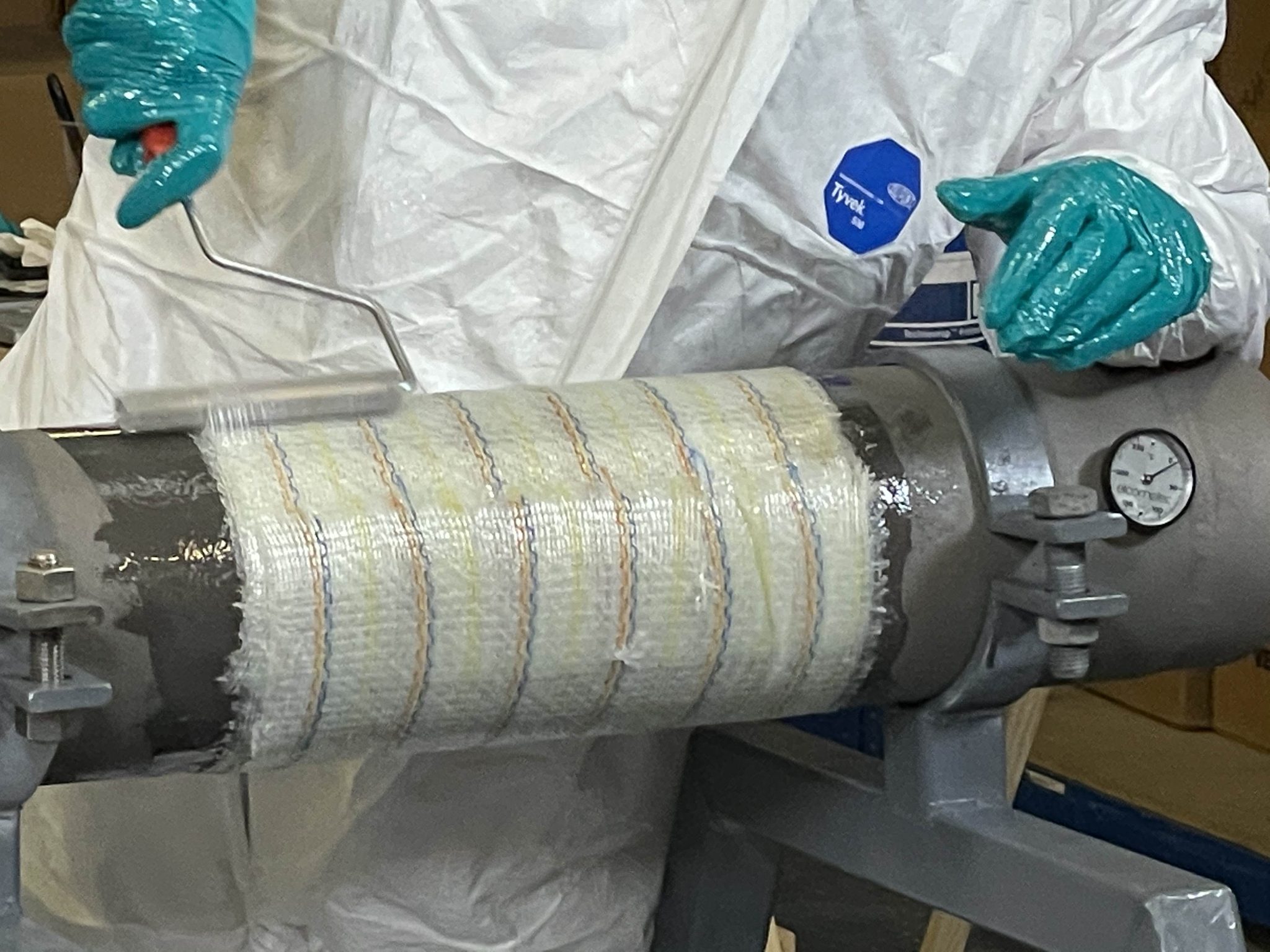

Technowrap™ is a versatile, long-term alternative to steel replacement, offering practical, cost-effective rehabilitation with minimal disruption to operations.

Applied to live targeted areas, without the need for shutdown or hot work, it supports safe operations while optimising production uptime, and delivers tangible cost savings along with environmental benefits.

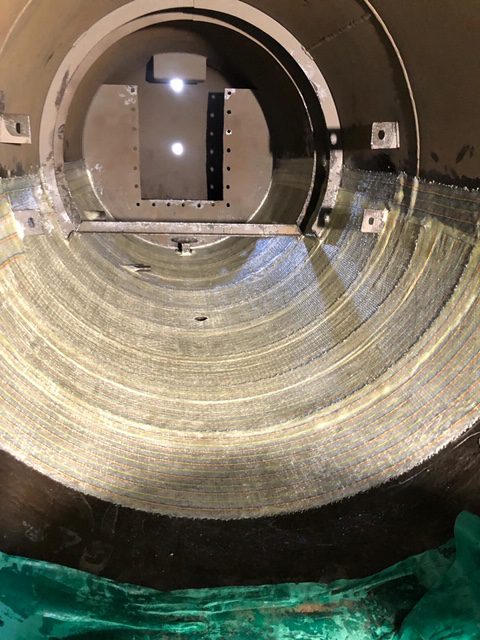

With over 30 years of experience and more than 50,000 composite repair applications worldwide, we are a market leader in composite repair technology. Our bespoke engineered repair systems use glass or carbon fibre stitched cloths combined with two-part epoxy resins, tailored to meet a wide range of mechanical and environmental requirements.

Technowrap™ in Marine

Technowrap™ can address common corrosion challenges caused by weathering, load fatigue, material degradation, ageing fleets, and more, and can repair a wide range of defect types, including thin- and through-wall, as well as internal and external corrosion. With approvals from Lloyd’s, ABS, and DNV, and no hot work required, Technowrap™ offers an optimal solution for addressing the corrosion challenges faced by the maritime industry.

Fleet Repairs

From commercial shipping fleets and offshore support vessels to ports, terminals, and naval and defence fleets, Technowrap™ provides a reliable and cost-effective solution for managing and restoring fleet integrity. With corrosion resistance and no hot work required, ICR’s composite repair technology can be installed with minimal disruption while ensuring a design life of up to 20 years.

Infrastructure Repairs

Technowrap™ can be used across a wide range of infrastructure repairs, including bridge rehabilitation, transport infrastructure such as railways and roads, and civil structures such as water tanks, tunnels, and buildings.

Training Personnel

Through our cost-effective training courses, your team will gain the knowledge required to carry out Technowrap™ composite repairs on simple geometries. Upon completion, delegates will be certified to apply Technowrap™ repairs on straight, bend, and tee pipe geometries, ensuring you’re safeguarded against the risks associated with urgent repairs.

Features, Advantages, and Benefits

Composite repairs can be analysed using INSONO™ – ICR’s composite inspection technology

Corrosion- and UV-resistant

Technowrap™ is highly versatile, with design flexibility to accommodate a wide range of materials, geometries, and operating conditions

Temperature range: -75°C (-103°F) to 230°C (446°F)

Pressure rating: Through-wall up to 70 bar / Thin-wall over 250 bar

Tested and qualified to ISO 24817 and ASME PCC-2 Article 401 standards

Case Studies & Further Information

Contact Us

Please fill out this form, or reach out to Dean Berry (dean.berry@icr-world.com), and our team will be in touch as soon as possible.