Client: Global Supermajor Operator

Location: Gulf of Mexico

Client challenge

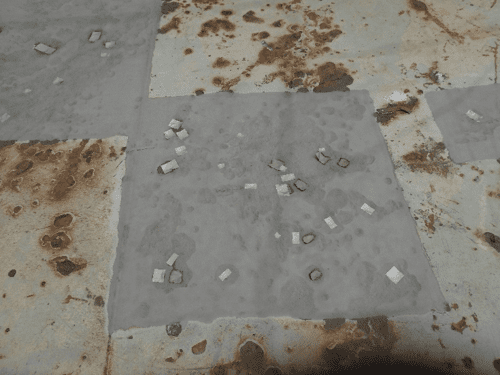

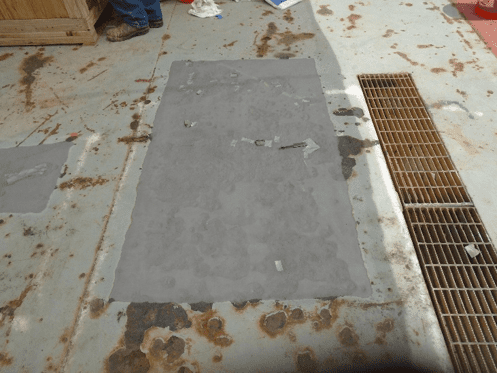

Onboard a supermajor’s platform, a logging support deck plate was identified to be suffering from external corrosion and various through-wall defects. Four distinct areas of the logging plate deck required immediate attention and composite repairs. The challenge was to address the corrosion issues and through-wall defects, ensuring the deck’s integrity and functionality.

What we did

Following a thorough engineering assessment, we proposed a comprehensive solution involving the application of four layers of Technowrap™ Structural carbon fiber combined with the DRS resin system over the identified defect areas. The design challenge was twofold – to ensure sufficient strength within the repair to withstand applied loads and to incorporate impact tolerance to withstand potential dropped objects. We developed a unique design methodology using rubber-toughened epoxy, providing the necessary strength, stiffness, and impact tolerance.

Results

The implementation of the Technowrap™ DRS repair solution resulted in successful outcomes and significant benefits:

Smooth application without delays: The application of Technowrap™ DRS proceeded as planned, without any delays. This efficiency minimized downtime and operational disruptions.

Restored deck integrity: The composite repair successfully restored the integrity of the logging support deck plate, addressing external corrosion and through-wall defects. The repaired areas were brought back to their original strength and functionality.

20-year defined lifetime: The engineered solution ensured the deck’s integrity for a defined lifetime of 20 years. This long-term reliability provided the client with assurance and sustainability.

The application of the Technowrap™ DRS repair system not only addressed the immediate challenges posed by external corrosion and through-wall defects but also provided a durable, impact-tolerant solution with a 20-year defined lifetime. This case study highlights the effectiveness of innovative composite repair methodologies in extending the lifespan and functionality of critical infrastructure in offshore environments.

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation