Client Challenge

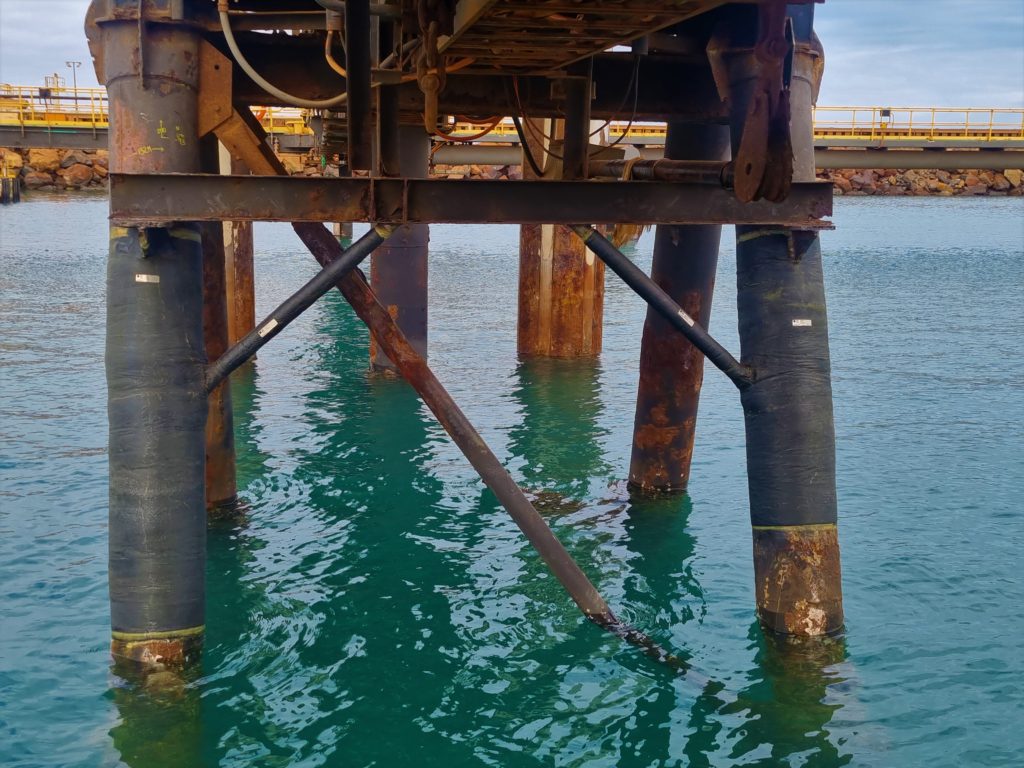

Our client, a global mining company based in Western Australia, faced a significant challenge with their coastal jetty piles. The structural steel piles exhibited extensive corrosion which drastically reduced their capacity and rendered the coastal jetty unusable for shipping mined products. In addition, the piles were coated with asbestos-containing material which required safe removal in order for adequate surface preparation for composite repairs. Furthermore, because of the coastal location, this presented significant challenges in terms of negotiating the tides and safely accessing the site.

What We Did

To effectively address our client’s challenges, we implemented a comprehensive strategy which involved carrying out the following processes:

Safe Asbestos Coating Removal

We prioritised the safe removal of the asbestos-containing coating to ensure a secure environment for subsequent repairs.

Advanced Engineering Calculations

Utilising advanced engineering calculations, we minimised the surface preparation area required for composite repairs, optimising efficiency and reducing risks associated with asbestos exposure.

Rope Access Technicians

Overcoming access challenges posed by the coastal location, we deployed highly skilled rope access technicians working from suspended platforms. This approach ensured precise execution of repairs even in challenging conditions.

Results

Our intervention yielded impressive results for the client by developing an innovative structural pile repair design methodology, specifically tailored to address the challenges posed by corroded piles. By leveraging advanced engineering calculations, we minimised the surface preparation area which reduced the risks associated with asbestos and enhanced overall project efficiency.

Our approach facilitated efficient repairs in areas with complicated geometry, ensuring seamless restoration of structural integrity. Beyond structural rehabilitation, our solution included comprehensive corrosion protection which distinguished it from traditional welded repairs that may remain susceptible to future corrosion. Additionally, our repairs successfully minimised the dead weight on the piles which helps to enhance structural stability and longevity.

In summary, our holistic approach not only addressed immediate structural challenges but also provided a sustainable and robust solution, ensuring the prolonged integrity of the coastal jetty piles.

Client Challenge

Our client, a major North Sea operator, faced a critical issue onboard one of their assets: a plenum chamber floor suffering from severe external corrosion. The corrosion buildup posed a threat of plate failure, with numerous areas developing through holes. Urgent action was needed to address the 36m² area requiring repair and prevent further deterioration.

What We Did

To tackle this challenge, we implemented an advanced engineered repair system. This comprehensive solution included precise design calculations and the installation of Technowrap™ DRS repair materials. Our skilled personnel, along with the materials, were deployed to reinstate the integrity of the affected floor areas. To mitigate concerns about potential turbine damage from loose grit, a final protective measure involved applying a thick coat of Technowrap™ DRS resin for a complete seal.

Results & Benefits

The application of Technowrap™ DRS proceeded smoothly, without delays, ensuring a timely repair for our major North Sea operator.

As an additional safety measure, an anti-slip coating was applied across the entire floor area, enhancing workplace safety.

The successful installation of Technowrap™ DRS effectively restored the integrity of the plenum chamber floor, providing long-lasting benefits and preventing further deterioration.

Client Challenge

A major energy operator in the Norway North Sea faced a significant issue with excessive corrosion which had led to several through-wall defects in a crucial 14” helideck drain line on their platform. The client sought a solution to repair and seal these defects, with the primary goal being a durable fix lasting at least 20 years.

What We Did

Our team addressed the challenge by implementing an engineered composite repair using the Technowrap 2K™ resin system. The design of the repair solution adhered to the rigorous standards outlined in ISO 24817.

Results & Benefits

The application of 8 layers of Technowrap 2K™ successfully restored the integrity of the pipework, ensuring a robust repair that is projected to last for an impressive 20 years.

This solution not only resolved the immediate issue but also provided long-term benefits, showcasing the effectiveness and reliability of our engineered composite repair approach.

Client Challenge

Three waste heat recovery unit roofs faced extensive external corrosion, leading to through-wall penetration in some areas and wall thinning in others. Our client needed a solution that would effectively reinstate the integrity and reinforce these roof sections, aiming for a 20-year repair lifetime. The challenge was compounded by the operating temperature of 220°C, requiring a repair method that could withstand the relevant loads and operate efficiently at elevated temperatures.

What We Did

We provided an engineered design for a 20-year repair lifetime, deploying Technowrap™ trained personnel, and utilizing Technowrap™ SRS HT carbon fiber materials for the repair. Given the severity of corrosion and the client’s preference to avoid grit blasting, ST3 Mechanical Preparation and ST2 hand preparation were used to achieve suitable surface finishes for bonding without causing further damage. To address the more severe corrosion than initially anticipated, wire mesh fillers were implemented and cured before the installation of the engineered Technowrap™ repairs. The operating temperature necessitated a temporary reduction to facilitate repair installation, with the heat from the units aiding in the curing process and reducing installation time.

Results & Benefits

Technowrap™ Structural Strengthening carbon fiber was meticulously applied using the hand lay-up technique, ensuring precise sizing of repairs and incorporating a slight taper at the edge of the panels.

The repairs were executed seamlessly while the units remained live, eliminating the need for isolation or shutdown, thereby preventing any loss of operation or production. The successful application of Technowrap™ SRS HT showcased its adaptability to high-temperature environments, offering a durable solution for waste heat recovery unit roofs.

Date: April 2018

Location: Middle East

Client challenge

A 30” Crude Oil Pipeline, located in the Middle East had previously suffered a through-wall defect. Initially, a clamp had been employed as the preferred repair method; however, this approach had proven ineffective and was actively leaking. The urgent task at hand was to provide a solution to repair the leaking clamp while the pipeline remained in operation and the leak persisted.

What we did

We leveraged our innovative composite repair technology, Technowrap™ 2K fibreglass cloth with HA (High Ambient) resins to repair the defect. We began by creating a sump, with a large threaded nut strategically positioned in the center of the cured composite cloth and maneuvered into place beneath the pipework. Ratchet straps were employed to secure the threaded nut in position. Once the initial repair around the nut was fully cured, layers were meticulously applied around the threaded nut, with the leak actively exiting at this point. Subsequently, a bolt was screwed into the thread, and the necessary number of layers was applied over the bolted area of the sump to secure and seal the repair effectively.

Results

The repair solution was successfully applied while the pipeline remained live, resulting in no downtime and zero impact on production and operational activities. This case study underscores our ability to provide swift and effective solutions, even under challenging circumstances, ensuring the seamless restoration of critical infrastructure without interrupting vital operations and production processes.

Client: Major Operator

Location: Qatar

Client challenge

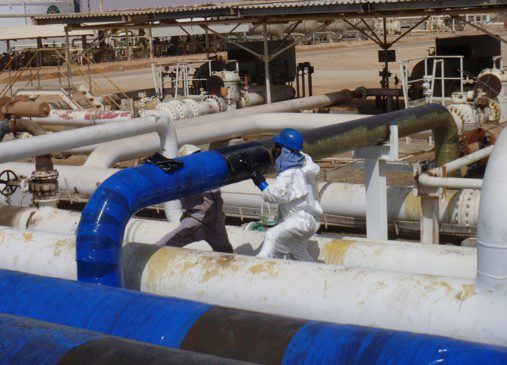

Our global partner in Qatar collaborated with a major oil and gas company to address the challenge of providing effective corrosion protection for subsea pipelines. The goal was to apply Technowrap™ 2K as a corrosion protection system, and the trial installation was initially conducted onshore. Subsequently, the protected pipe lengths were transported offshore using a pipe lay barge and installed on the seabed.

What we did

The project covered a range of pipe diameters, including 6”, 8”, 10”, and 12”. After a successful trial, this process was extended to a subsea hydrocarbon and gas pipeline spanning 12 kilometers. Prior to the trial, both our client and contractors conducted extensive testing and inspections to ensure the efficacy of the corrosion protection system. The trial itself took 12-14 weeks to complete, with a crew of six Technowrap™ 2K Installers working on a 24-hour, 12-hour rotation to encapsulate the various welds with layers of Technowrap™ 2K composite repair following hydrotesting of the welded pipe sections.

Results

Our composite repair system demonstrated remarkable success in this application and received approval for corrosion protection applications. In this specific trial, our client requested a longer service life, ranging from 25 to 30 years, exceeding the standard lifetime designs of up to 20 years. Through a meticulously engineered solution, a 25-30 years lifetime could be provided, surpassing the longevity of any other paint and epoxy system available on the market.

Client challenge

Our client faced a critical challenge when a catastrophic failure occurred in their 56-inch water export line, resulting in a 1.7-meter-long rupture. Concerns arose regarding the possibility of similar defects within the line were compounded by several critical factors, including:

Operating the 56” water export line under a high line pressure of 22 bar, heightened safety concerns regarding the potential for injury resulting from a breach.

The consequential loss of production due to the interruption of the injected water supply.

The catastrophic rupture’s root cause was identified as seam weld root corrosion, compelling the replacement of the damaged section and the launch of a comprehensive preventative maintenance campaign covering the entire pipeline.

What we did

In response to the urgent need for a solution, we provided our client with an engineered design, materials, and skilled labor within a 24-hour timeframe. Our approach focused on designing a seven layer engineered Technowrap™ SRS repair solution specifically aimed at structurally restoring the integrity of the pipework, effectively preventing future seam weld ruptures.

Results

The rapid implementation of our solution yielded significant results and benefits:

The quick restoration of the water export line, with it becoming operational only four days after the initial rupture, played a pivotal role in minimising downtime. This achievement not only eliminated the need for costly and time-consuming pipe replacement but also resulted in substantial cost savings. Additionally, our prompt resolution of critical health, safety, and environmental concerns related to the rupture allowed other essential work to continue seamlessly in the area. Moreover, our intervention significantly reduced lost production time, mitigating financial losses, and ensuring the uninterrupted flow of injected water.

This case study underscores our unwavering commitment to delivering timely and effective solutions to clients grappling with catastrophic failures, thereby facilitating the swift restoration of critical infrastructure and minimizing the associated economic and operational disruptions.

Client challenge

Our client’s 32” produced water line, was exhibiting significant internal erosion and corrosion, leaving a minimum remaining wall thickness of just 4mm. The extensive scope of the repair encompassed approximately 550 meters of pipeline, including various saddle supports, some of which were welded. The client also stipulated the need for a qualification test for the proposed repair solution, to be conducted on-site before the actual repair implementation.

What we did

Our solution began by defining a comprehensive scope of work, which included engineering an innovative design to ensure a 20-year repair lifetime. This encompassed providing trained personnel and the necessary materials, specifically Technowrap™ 2K with Technowrap™ HP PRS, to execute the repair. The line’s design parameters included a pressure of 47 bar g and a temperature of 82ºC. We meticulously developed an installation procedure for the composite repair, which was thoroughly tested and approved by the client before on-site installation. To ensure complete encapsulation of the pipeline, we also devised a detailed lifting plan for the pipeline over the supports. This plan addressed additional requirements, including applying the repair in areas where the pipework rested on the pipe supports.

Results

The execution of the qualification test was a resounding success, meeting the client’s approval and verifying the effectiveness of the repair solution. The repair was installed, confidently meeting the design pressure of 47 bar g and operating within the specified temperature range of 82ºC. Our detailed lifting plan was meticulously executed, ensuring the complete encapsulation of the pipeline. This case study showcases our dedication to delivering reliable and enduring solutions, providing clients with the confidence to address complex challenges in maintaining critical infrastructure.

Client challenge

Our client faced a challenge involving their filter house which had multiple defects, causing water loss and impacting production. To address this issue, a four day shutdown was planned to execute repairs. The primary objectives were to restore the full integrity of the pipework and prevent further water loss, and maximise production efficiency.

What we did

During the four day shutdown, we executed a series of fully engineered Technowrap™ 2K rehabilitation system repairs to address the identified defects. These repairs encompassed a variety of diameters (24” and 40”) and geometries (straight, bend, tee-piece), with design parameters including a design pressure of 2.5 bar and a design temperature of 500ºC. The selected resin system was High Ambient 2-part Epoxy Resin, offering a repair lifetime of five years.

Results

The shutdown proved highly productive and resulted in several key benefits including;

During the allocated four day timeframe, a total of 15 severe leaks were expertly sealed and repaired, eliminating the need for costly line replacement and providing a highly cost-effective solution. We played a pivotal role in ensuring the success of this project by offering comprehensive support, including pre-shutdown site surveys, task-based risk assessments, design calculations, and surface preparations to guarantee the safety and accessibility of all repair areas.

The execution of the shutdown scope proceeded flawlessly in accordance with the agreed plan and all through-wall defects were effectively sealed using Technowrap™ 2K plates, with repairs skillfully installed to encapsulate the plates for the required minimum length. Rigorous QA/QC checks were diligently completed before station start-up, ensuring the highest standards of quality. Importantly, the entire scope was executed without any incidents, underscoring our unwavering commitment to safety and efficiency. This case study serves as a testament to our remarkable ability to swiftly and effectively address complex repair challenges during critical shutdowns, ultimately enhancing production and minimizing operational disruptions.

Date: May 2023

Client: International independent E&P company

Location: Dutch North Sea

Client challenge

Our client is an international independent exploration and production (E&P) company operating in the Dutch North Sea. They approached our team with a critical structural repair project involving the repair of ten beams with complex geometries and required a solution that could achieve compression on corroded beams. The objective was to provide a long-term, cost-effective repair solution while ensuring the safe operation of the bridge link. The structural repair of the bridge link beams presented several challenges that needed to be addressed.

The complexity of the beams required a solution capable of forming around the unique geometry. Additionally, achieving compression on corroded beams was crucial to ensure adequate adhesion of the repaired elements. The repair was carried out without the need for fabrication, hot work, or heavy lifting to minimise downtime and associated costs. The chosen solution required a design life of 20 years to align with the remaining lifespan of the asset.

What we did

To meet the specific requirements of the structural repair, our team employed a combination of two advanced fabric systems:

- Technowrap™ SRS (Structural Repair System)

- Technowrap™ HPPRS (High-Pressure Pipe Repair System)

By combining these fabrics, we created a bespoke laminate solution tailored to the unique repair scenario of the bridge link beams.

The repair process involved the following steps:

Assessment and preparation: The bridge link beams were thoroughly assessed to identify the extent of corrosion and damage. The corroded areas were cleaned and prepared for the application of the composite repair system.

Fabric selection and laminate formation: Technowrap™ SRS and Technowrap™ HPPRS fabrics were selected based on their individual strengths and characteristics. A customised laminate was created, leveraging the unique properties of each fabric to achieve optimal strength in the correct load path.

Application: A supervisor and two technicians were deployed to carry out the repair. The laminate system was applied to the bridge link beams, ensuring full coverage and conformity to the complex geometries of the structures. The installation process required no fabrication, hot work, or heavy lifting, streamlining the repair and minimising downtime.

Quality assurance and longevity: Rigorous quality assurance measures were implemented to verify the effectiveness of the repair. The composite laminate solution was designed to provide a 20-year design life, aligning with the remaining asset life.

Results

The successful implementation of the composite repair solution for the bridge link beams provided several outcomes and benefits, providing a long-term solution designed to last the remaining 20-year life of the asset. This ensured the continued safe operation of the bridge link and minimised the need for future repairs or replacements. Additionally, the repair solution required no fabrication, hot work, or heavy lifting. This streamlined the installation process, reducing downtime and associated costs. In terms of cost, the composite repair solution offered a cost-effective alternative to full beam replacement, saving the client significant expenses while maintaining structural integrity.

The quick application of the repair solution ensured the safe future operation of the bridge link and the repaired beams were capable of withstanding the operational loads and environmental conditions in the Dutch North Sea.

The structural repair project for the bridge link beams showcased our team’s expertise in developing and implementing advanced composite solutions for complex geometries. By combining Technowrap™ SRS and Technowrap™ HPPRS fabrics, we successfully addressed the challenges posed by the client. The efficient, cost-effective, and reliable repair solution enabled the client to continue safe operations and provided longevity of the asset in the Dutch North Sea.