Client Challenge

A North Sea operator had a platform which was experiencing significant corrosion on the west side stairs. This corrosion threatened the integrity and safety of the stairs, necessitating immediate attention to prevent further deterioration and potential safety hazards. Additionally, five 3” stanchion supports were suffering wall loss due to external corrosion, requiring preventative measures to avoid further damage. The complexity of the project was compounded by weather delays and equipment limitations, which impacted the feasibility of completing all necessary repairs in a single mobilisation.

What we did

To address the challenges posed by the corroded stairs and stanchion supports, we mobilised a team of two skilled rope access technicians to the platform. The repair process was meticulously planned and executed in several stages to ensure comprehensive and lasting results:

Surface preparation: The technicians performed thorough surface preparation to achieve ST3 cleanliness, essential for the effectiveness of the subsequent repair layers.

Primer application: After preparing the surface, a 3K primer was applied to the repair area, forming a strong foundation for the following layers.

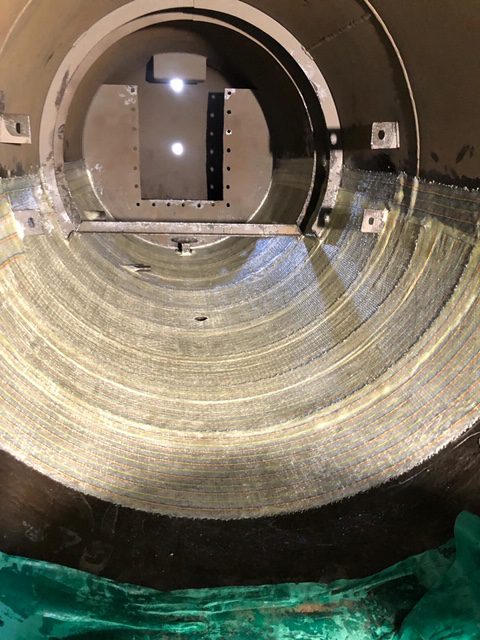

Layer application: The technicians applied five layers of our carbon-fibre SRS cloth, combined with a 2K LT resin system (Low Temperature – suitable for North Sea applications). To reinstate full structural support to the gratings placed on top, the underside of the top lip of the beams received ten layers of cloth.

Stanchion support repair: Two layers of 2K LT were applied to the five 3” stanchion supports experiencing wall loss due to corrosion, as these supports had no structural loading.

Results

The repair work carried out resulted in full reinstatement of the integrity and safety of the affected areas. The application of the carbon-fibre SRS cloth and the flexible wet layup process ensured a durable and effective solution to the corrosion problem, despite challenging geometry and access conditions.

Enhanced structural integrity: The under-deck stairs now have restored integrity, with the Technowrap repair providing robust protection against further corrosion. The stairway is now back in use, eliminating the hazard potential for staff on the asset.

Preventive measures: The stanchion supports were effectively safeguarded from further corrosion, extending their operational life and preventing potential future issues.

Additional verification: Due to the structural loadings in the stairway, and the level of wall loss across the beams, a review of the design calculations, repair methodology, and close out reports was carried out by Lloyd’s Register. They

requested additional information on the justification for the design, considering the lifetime of the repair, required loadings and material condition and properties of the staircase and stanchion supports.

The successful review by Lloyd’s Register once again proved the composite wrap solution is valid for structural components and where a cold works solution is needed.

Professional execution: Despite the challenges posed by weather, our technicians completed the critical parts of the project efficiently and to high standards, ensuring minimal disruption to the platform’s operations.

The effective mobilisation and execution of this repair project further highlights our expertise in addressing complex corrosion issues in challenging offshore environments, providing operators with a reliable partner for maintaining their assets.

Client: Global operator

Location: Offshore Trinidad & Tobago

Client challenge

In collaboration with local partner H.J. Stauble, our client faced the challenge of providing a cold work solution to refurbish a main deck on an online platform which had multiple areas of corrosion. They required a solution that not only addressed the corrosion issues, but also complied with stringent testing criteria to prove the suitability of the engineered composite repair. The platform’s operational status added an additional layer of complexity to the refurbishment.

What we did

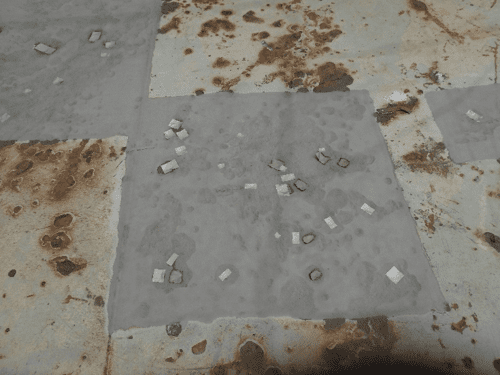

In response to our client’s challenge, we conducted a series of comprehensive tests to validate the effectiveness of the engineered composite repair solution. Impact and lateral restraint testing were crucial aspects. A 400 lbs/ft2 weight was dropped from a 1.2m height onto the test laminate, and the same weight was dragged laterally to assess lateral restraint. These tests were repeated 10 times. Among the four composite repair bidders, our deck repair solution emerged as the only one to withstand the full drop and lateral restraint testing without disbondment, leading to the award of the scope of work.

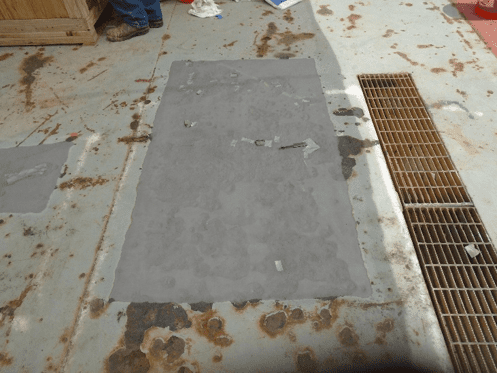

The selected solution involved various design methodologies based on loading requirements provided by the client. This ranged from 2 to 6 layers of our Technowrap™ DRS repair system. Grit blasting was employed for surface preparation, ensuring SA2.5 cleanliness.

Results

The implementation of the Technowrap™ DRS repair system resulted in several positive outcomes:

Restoration of deck integrity: The main deck’s integrity was successfully restored, addressing the multiple areas of corrosion.

Compliance with applied load/pressure: The repaired deck areas complied with an applied load/pressure of 400 lbs/ft2, meeting the client’s stringent requirements.

Enhanced damage tolerance: The inclusion of rubber-toughened nano particles in the DRS resins contributed to increased damage tolerance, ensuring long-term durability.

Engineered design life: All repaired deck areas were designed with an engineered lifespan of 10 years, providing a reliable and sustainable solution.

Timely Installation with No Production Impact: The repairs were installed without delays, and the process had no impact on ongoing production activities.

No heavy lifting or steel components: The cold work solution involved no heavy lifting or the addition of steel components, minimizing logistical complexities.

The successful application of the Technowrap™ DRS repair system not only addressed the corrosion challenges on the main deck but also showcased its resilience through rigorous testing, providing the client with a reliable, durable, and non-disruptive solution.

Client: Global Supermajor Operator

Location: Gulf of Mexico

Client challenge

Onboard a supermajor’s platform, a logging support deck plate was identified to be suffering from external corrosion and various through-wall defects. Four distinct areas of the logging plate deck required immediate attention and composite repairs. The challenge was to address the corrosion issues and through-wall defects, ensuring the deck’s integrity and functionality.

What we did

Following a thorough engineering assessment, we proposed a comprehensive solution involving the application of four layers of Technowrap™ Structural carbon fiber combined with the DRS resin system over the identified defect areas. The design challenge was twofold – to ensure sufficient strength within the repair to withstand applied loads and to incorporate impact tolerance to withstand potential dropped objects. We developed a unique design methodology using rubber-toughened epoxy, providing the necessary strength, stiffness, and impact tolerance.

Results

The implementation of the Technowrap™ DRS repair solution resulted in successful outcomes and significant benefits:

Smooth application without delays: The application of Technowrap™ DRS proceeded as planned, without any delays. This efficiency minimized downtime and operational disruptions.

Restored deck integrity: The composite repair successfully restored the integrity of the logging support deck plate, addressing external corrosion and through-wall defects. The repaired areas were brought back to their original strength and functionality.

20-year defined lifetime: The engineered solution ensured the deck’s integrity for a defined lifetime of 20 years. This long-term reliability provided the client with assurance and sustainability.

The application of the Technowrap™ DRS repair system not only addressed the immediate challenges posed by external corrosion and through-wall defects but also provided a durable, impact-tolerant solution with a 20-year defined lifetime. This case study highlights the effectiveness of innovative composite repair methodologies in extending the lifespan and functionality of critical infrastructure in offshore environments.

Client: Major operator

Location: US – Texas Eagle Ford Basin

Client challenge

During routine flange maintenance work on a 16” transmission line, our client observed concerning issues with the protective bitumastic wrap. A subsequent inspection revealed the deterioration of the wrap and significant corrosion in the exposed area. Faced with the potential operational and environmental risks, it was essential that this was addressed immediately.

What we did

To mitigate the corrosion risks and extend the life of the affected area, our team implemented an engineered composite wrap solution using WTR 12068. The pipe underwent meticulous preparation to SP 3 standards, ensuring a clean and suitable surface for the application. Eight layers of Technowrap, designed to provide enhanced protection, were applied to the compromised section of the 16” transmission line.

The decision to opt for an engineered composite wrap aimed to provide a targeted and efficient solution, minimizing downtime and avoiding the need for a complete pipeline replacement. This approach also eliminated the necessity for hot works, ensuring a safer and more environmentally friendly execution.

Results

The outcomes of our intervention exceeded expectations, offering several key benefits to our client:

Preservation of the Existing Line: The implementation of the engineered composite wrap successfully preserved the 16” transmission line, eliminating the need for a costly and time-consuming replacement.

Elimination of Hot Works: The chosen solution avoided the use of hot works, mitigating safety risks and environmental concerns associated with traditional repair methods.

Life Extension Achieved: The application of the engineered composite wrap, comprising eight layers of Tecnhowrap, provided a targeted five-year life extension to the affected area. This ensured the continued reliability and functionality of the transmission line.

This case study underscores the effectiveness of strategic interventions in preserving the integrity of crucial infrastructure. By choosing an engineered composite wrap solution tailored to the specific challenges faced by the 16” transmission line, we successfully addressed the client’s concerns while delivering long-term benefits in terms of safety, efficiency, and operational continuity.

Client challenge

A client approached our team with a critical challenge involving the production chemical injection skip pan, which was experiencing localized pitting, wall loss, and through-wall defects of varying sizes. While structural capacity was a minor consideration due to small loads, the primary goal was to reinstate the skip pan’s integrity to ensure effective containment of fluids. We were was tasked with providing a solution that addressed the defects and maintained the production process’s reliability.

What we did

In response to the client’s challenge, we devised a comprehensive solution to rehabilitate the production chemical injection skip pan. The proposed repair involved the application of two layers of Technowrap 2K™ substrate with Technowrap HA™ (High Ambient) resin, supplemented by localized plates strategically placed over the through-wall defects. The repair covered the entire skip pan, ensuring the proper pan gradient for fluid drainage. With a design life of 10 years, a fluid loading of 20 psf, and a maximum temperature of 120ºF, the composite repair was engineered to share the load with the existing steel structure, assuming an average remaining wall thickness of 0.125” (3.175mm).

One notable challenge encountered during the application was limited space access which we overcame by fabricating a custom roller with an extension. This innovative solution enabled the application of Technowrap 2K™ in the cramped working area between the equipment and the skip pan catch basin.

Results

The implemented composite repair solution yielded positive results and notable benefits:

10-Year Defined Life: The repair was engineered to provide a 10-year defined life, ensuring the longevity and reliability of the skip pan.

Safety and Compliance: No hot work was required during the repair process, significantly reducing safety risks and ensuring compliance with stringent safety standards.

Cost-Effective Alternative: The composite repair solution proved to be a cost-effective alternative when compared to the traditional approach of welded replacement, providing significant cost savings for the client.

Minimal Personnel Onboard (POB) Requirements: The repair was executed with minimal POB requirements, contributing to operational efficiency and cost-effectiveness.

In conclusion, our innovative composite repair not only addressed the client’s challenges related to the production chemical injection skip pan but also provided long-term reliability, safety, and cost-effectiveness. This case study highlights the adaptability of composite repair solutions in overcoming complex challenges in industrial settings.

Client: Talos Energy

Asset: Offshore platform

Location: Gulf of Mexico

Client challenge

A major operator in the Gulf of Mexico faced a critical issue with a carbon steel section of a methanol drip pan on their platform. The structure exhibited localized pitting, wall loss, and through-wall defects of varying sizes, necessitating immediate attention. The client approached ICR with the challenge of providing an engineered composite repair solution that would ensure a 10- year design life. The primary focus was on containing fluids, considering minor structural capacity and aiming for a cost-effective alternative to welded replacements.

What we did

To address the client’s challenge, we implemented a comprehensive solution utilizing two layers of Technowrap 2K™ glass fiber combined with Technowrap HA™ (High Ambient) resin. Localized plates were strategically placed over numerous through-wall defects, ensuring a holistic coverage of the entire drip pan. The design parameters included a 10-year lifespan, a fluid loading of 20 psf, and a maximum temperature of 120ºF. The composite repair was engineered to share the load with the existing steel structure, assuming an average remaining wall thickness of 0.125” (3.175mm).

Results

The implemented composite repair solution achieved significant results and benefits for our client:

Cost effectiveness: After multiple drip pan repairs with various operators, it was established that the composite repair method proved to be extremely cost-effective compared to the alternative of a welded replacement.

Efficiency in installation: The repair process was swift, reducing downtime and operational disruption. Its efficiency was further highlighted by the elimination of hot work requirements, significantly decreasing safety risks associated with traditional repair methods.

Minimal Personnel Onboard (POB) requirements: The repair was executed with a minimal crew, requiring only one Rope Access supervisor. This not only streamlined the installation process but also contributed to a reduction in overall project costs and logistical complexities.

In conclusion our engineered composite repair not only met the client’s requirements for a 10-year design life and fluid containment but also demonstrated notable advantages in terms of cost-effectiveness, efficiency, and safety. This case study underscores the effectiveness of composite repair solutions in extending the lifespan of critical infrastructure in challenging offshore environments.

Client challenge

Our client, an energy operator based in North America, faced a significant challenge with their main crude export line, which extended from a tank farm to a loading berth at sea. Erosion of the bitumastic coating at the transition zone had led to accelerated corrosion and isolated leaks had emerged, necessitating mechanical clamping. Further inspection revealed corrosion had progressed beneath the coating, resulting in substantial wall loss, particularly between the 5pm and 7pm positions on the pipe. Given the line’s critical nature and frequent use, a decision had to be made to address the issue without replacing the entire section of the pipe.

What we did

To address our client’s challenge, our team opted for an engineered wrap solution at the transition zone. Two designs were developed – WTR 11280 for thin-wall sections and 11280 through-wall – aiming to provide a twenty-year life extension. The existing failing wrap and mechanical clamps were removed, and the pipe underwent preparation to SP 6 standards. Subsequently, four layers of the engineered wrap were applied to the thin-wall sections, while eight layers were applied to the through-wall areas.

The execution of the project was carefully planned to coincide with windows between shipments when the line could be depressurized and de-inventoried, ensuring adherence to Health, Safety, and Environment (HSE) protocols. The initial scope of the project covered a 100-foot section of the pipeline.

Results

The implementation of the engineered wrap solution proved successful in mitigating the corrosion risks in the critical crude export line. The transition zone, once prone to erosion and accelerated corrosion, now boasts enhanced protection and a renewed structural integrity. The engineered wrap, with its thin-wall and through-wall designs, has provided a twenty-year life extension, meeting the client’s requirements for long-term reliability.

This case study highlights the efficacy of our solution in addressing complex challenges in critical infrastructure, emphasizing the importance of tailored engineering interventions to extend the life of essential assets while minimizing downtime and ensuring environmental and operational safety.

Client challenge

Our client, an energy operator in the US, faced a significant challenge with the deteriorating condition of an offshore deck, primarily due to exposure to harsh environmental elements. The existing deck structure, originally constructed with bare steel, exhibited signs of wear, necessitating a solution that would not only address the current issues but also ensure long-term durability. The client’s key requirements included achieving a twenty-year life extension, minimizing downtime, eliminating hot works, and enhancing the overall aesthetics and safety of the deck.

What we did

To meet our client’s challenge, we used our Technowrap™ engineered composite repairs solution to provide durable rehabilitation and extended service life. The process involved transforming the deck from bare steel to a fully covered, non-skid surface within days.

The application of Technowrap™ was meticulously executed to ensure a seamless transition. The innovative system not only addressed the existing wear and tear, but also provided a robust protective layer against future environmental challenges.

Crucially, the rehabilitation process was completed without any downtime for the operator, and the entire operation was carried out without resorting to hot works, ensuring a safe and efficient execution.

Results

The implementation of our Technowrap solution produced sustainable results:

Twenty-year life extension: The deck rehabilitation successfully achieved the client’s objective of a twenty-year life extension, ensuring prolonged structural integrity and functionality.

Efficient transformation: The transformation from a bare steel deck to a fully covered non-skid surface was accomplished within a few days, minimizing disruption to ongoing operations.

No downtime or hot works: The rehabilitation process was conducted seamlessly without any operational downtime or the need for hot works, ensuring operator safety and environmental compliance.

Aesthetically pleasing and weather-resistant: Three years post-rehabilitation, the deck not only retained its structural integrity, but also maintained an appealing appearance, standing up to the challenges posed by the elements.

This case study highlights the successful application of our engineered composite repair solution, Technowrap™, in addressing complex challenges associated with offshore deck rehabilitation. The project’s positive outcomes underscore the effectiveness of advanced composite solutions in achieving long-term durability, safety, and aesthetic improvements in offshore infrastructure.

Client challenge

During routine flange maintenance work on a 16” transmission line, our client observed concerning issues with the protective bitumastic wrap. A subsequent inspection revealed the deterioration of the wrap and significant corrosion in the exposed area. Faced with the potential operational and environmental risks, it was essential that this was addressed immediately.

What we did

To mitigate the corrosion risks and extend the life of the affected area, our team implemented an engineered composite wrap solution using WTR 12068. The pipe underwent meticulous preparation to SP 3 standards, ensuring a clean and suitable surface for the application. Eight layers of Technowrap, designed to provide enhanced protection, were applied to the compromised section of the 16” transmission line.

The decision to opt for an engineered composite wrap aimed to provide a targeted and efficient solution, minimizing downtime and avoiding the need for a complete pipeline replacement. This approach also eliminated the necessity for hot works, ensuring a safer and more environmentally friendly execution.

Results

The outcomes of our intervention exceeded expectations, offering several key benefits to our client:

Preservation of the Existing Line: The implementation of the engineered composite wrap successfully preserved the 16” transmission line, eliminating the need for a costly and time-consuming replacement.

Elimination of Hot Works: The chosen solution avoided the use of hot works, mitigating safety risks and environmental concerns associated with traditional repair methods.

Life Extension Achieved: The application of the engineered composite wrap, comprising eight layers of Tecnhowrap, provided a targeted five-year life extension to the affected area. This ensured the continued reliability and functionality of the transmission line.

This case study underscores the effectiveness of strategic interventions in preserving the integrity of crucial infrastructure. By choosing an engineered composite wrap solution tailored to the specific challenges faced by the 16” transmission line, we successfully addressed the client’s concerns while delivering long-term benefits in terms of safety, efficiency, and operational continuity.

Client challenge

Several I-beam walkway supports faced severe corrosion issues, including through-wall penetration in both the flange and web sections, necessitating a restoration of their structural integrity. Our client needed a solution that avoided the high cost and unacceptable hot work associated with the like-for-like replacement of the supports.

What we did

Our approach involved providing an engineered design, implementing a Technowrap™ Structural Strengthening repair solution, and deploying trained personnel for the repairs. The repair design was meticulously crafted to withstand full applied loads, with a targeted design life of 20 years as per the client’s specifications. The complexity of the corroded beam areas required the use of a hand lay-up technique, as prefabricated plates were not feasible. ICR personnel underwent extensive training and testing at the Aberdeen headquarters, mastering various structural scenarios to ensure the effective application of repairs to intricate geometries.

Results

A Technowrap™ carbon fibre structural solution was successfully applied to the external surfaces of the supports, reinstating the integrity of the structure and the repairs were executed seamlessly while the platform remained in operation and production, eliminating the need for isolations, downtime, or platform shutdowns. The before-and-after visuals depict a notable transformation, showcasing the effectiveness of the implemented solution in restoring the I-beam walkway supports to their optimal condition.