Scope

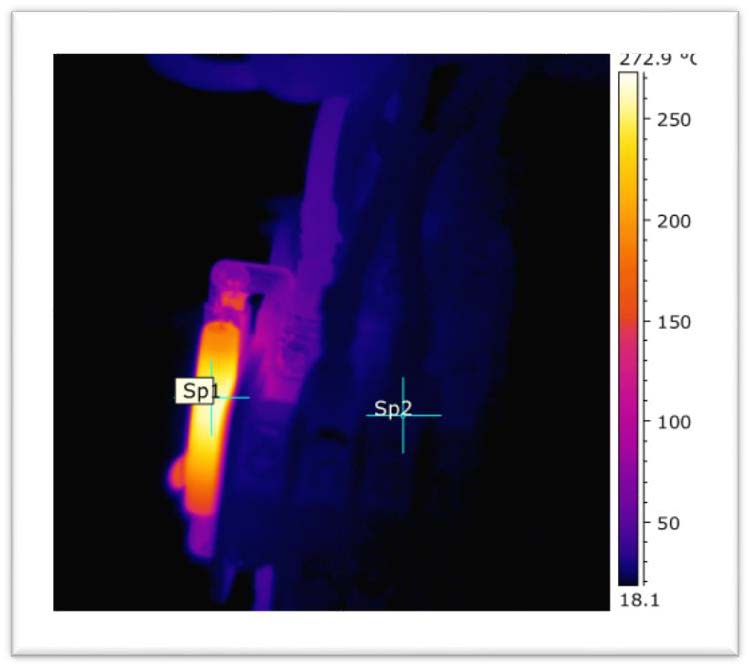

We were requested by an Oil and Gas Operator to conduct a non-intrusive thermal imaging survey on an offshore un-manned platform. The main aim of the workscope was to survey electrical switchboards, distribution boards, control panels, busbars, transformers etc and identify, if any, hotspots that were above the normal operating temperature for the equipment. The risk with electrical components overheating is that they can cause the platform system to trip/shutdown or pose spark potential/fire risk in worse case scenario. The work was carried out while the plant was online using the FLIR T320 thermal imaging camera.

Solution

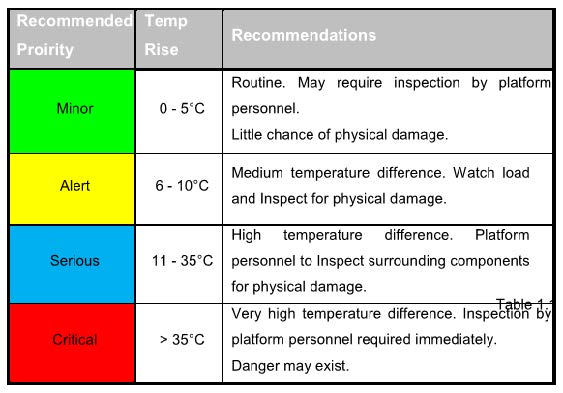

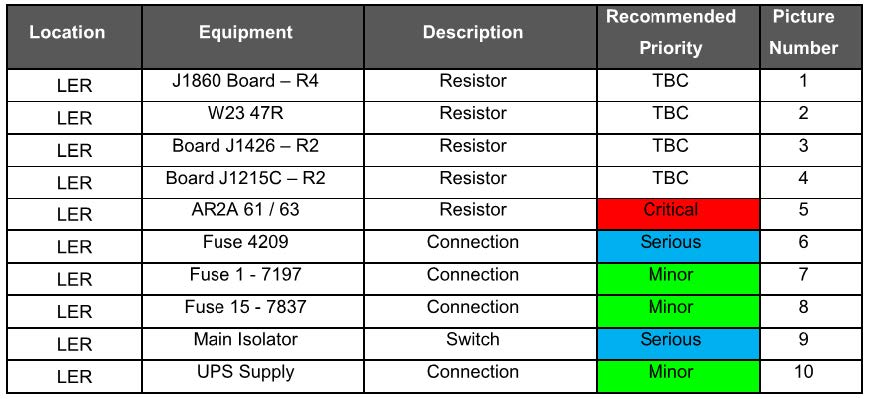

All electrical components noted to have “hot spots” or found to be above ambient or operating temperature were recorded in accordance with the BSRIA standard of LV Electrical Installations FMS 5/99 (see table). During the survey it was noted that several components displayed temperatures significantly above ambient and, potentially, operating temperature.

Results & Benefits

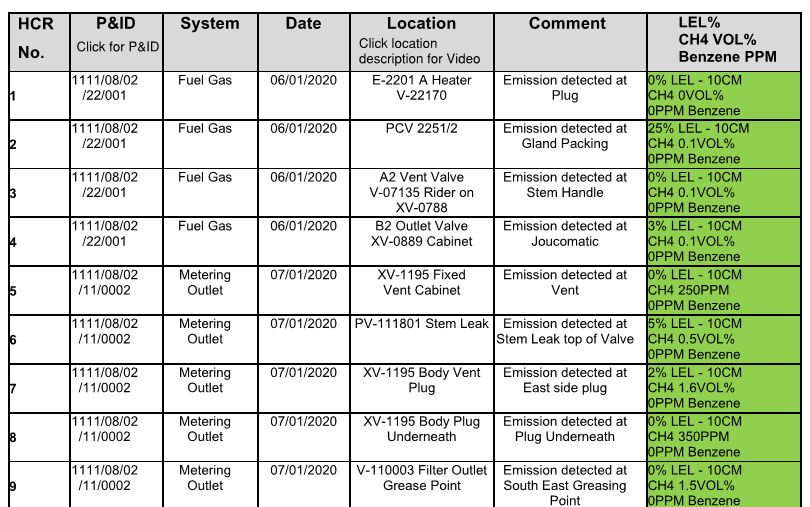

- All results were populated in a table (example left) and rated accordingly using the BSRIA standard. A full report was also issued to the client so they could review the findings and act accordingly.

- Following review of the final report the client was able to arrange repair and replacement of the components. The client believed that the survey was of great value as they would not have been able to identify these issues otherwise. As they were able to rectify the issues it reduced the risk of any unplanned shutdowns and outages caused by faulty electrical components which is of great benefit to unmanned platforms and can provide significant cost saving benefits long term. Routine thermography inspections have now been planned on a yearly basis across all of the clients assets.

Resistor displaying temperature of 250 degrees which is significantly above ambient and operating temperature. This was classed as a serious priority.

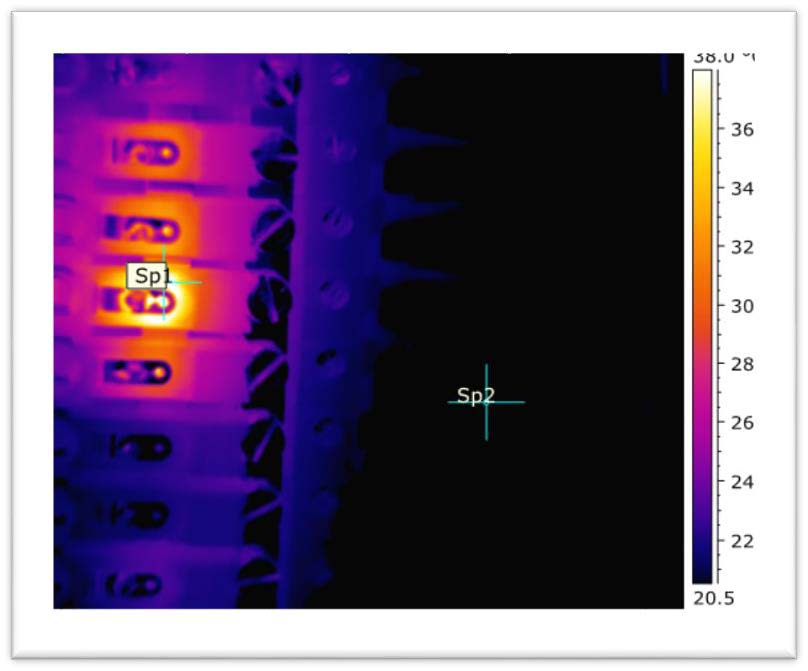

Fuse displaying temperature of 20 degrees above ambient and operating temperature.

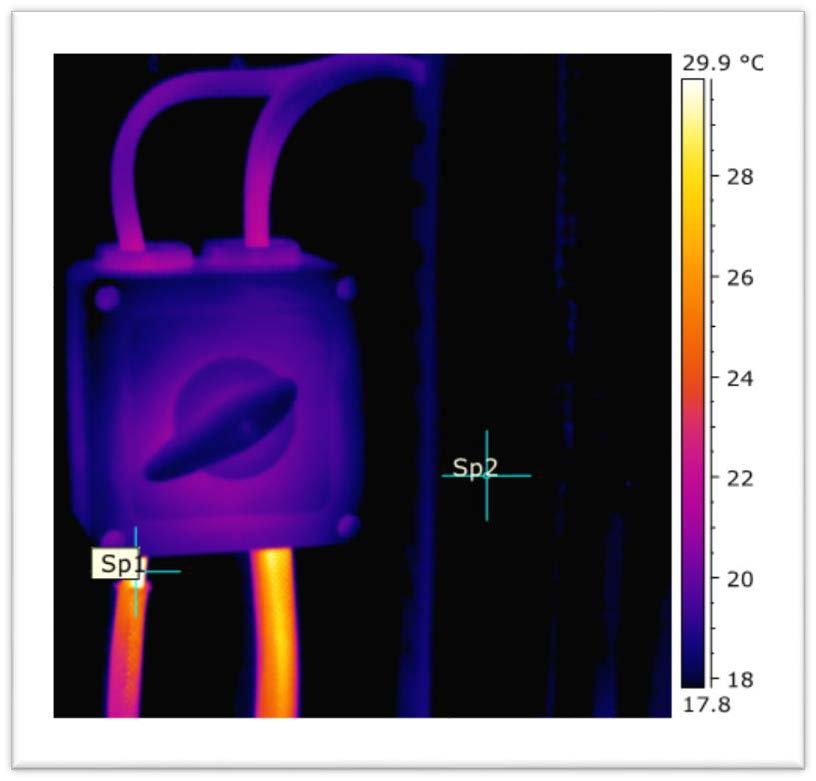

Cables from main isolator switch displaying temperature of 15 degrees above ambient and operating temperature. There is also damage noted to one of the cables.

| Date | Client | Location |

|---|---|---|

| January 2020 | Global Operator | UK Onshore Gas Terminal |

Scope

Our client wanted to improve their strategy and planning for detecting and repairing hydrocarbon releases across their gas terminal. Previous surveys had been intermittent with minimal traceability with regards to current releases and repaired releases.

Solution

We proposed quarterly visits to the terminal where all areas would be surveyed by the ICR technician using an FLIR GF320 camera and Inficon Irwin methane detector. Each hydrocarbon release found with the camera would be recorded and tagged, the LEL and Methane quantification (in PPM or %) also noted in order to gauge severity of the release. This is reported to the client in spreadsheet format along with highlighted P&ID’s and video footage.

Results & Benefits

- Using the report the client is able to repair the hydrocarbon releases in order of severity and work through the list.

- During the next quarterly visit ICR would conduct another full survey including all the historical hydrocarbon releases.

- The releases repaired would be removed from the spreadsheet and any new releases found would be added.

- Again all this would be reported to the client. The hydrocarbon release spreadsheet would effectively become a live document for the client to access and would be updated quarterly by ICR.

- Routine surveys like this can offer significant safety and cost saving benefits long term.

Scope

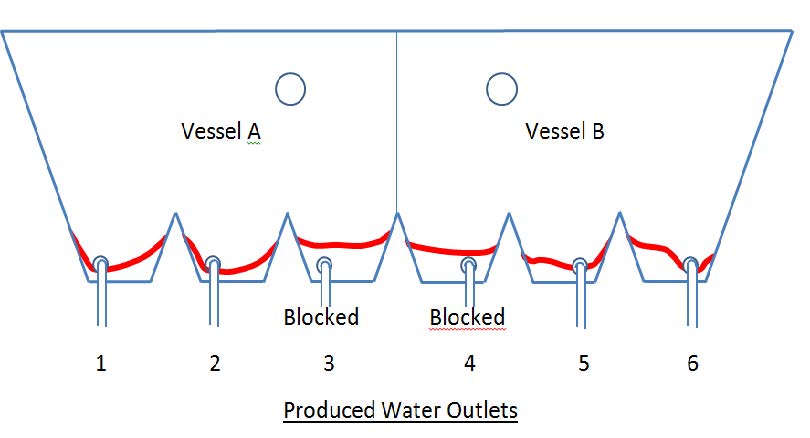

Our client required a non-intrusive inspection method capable of identifying the presence of sand/solid levels believed to be present within a tilt plate separator. The separator was located on an offshore production facility which has been in operation since 1986. The production system present on the facility is capable of processing 31,000 bpd.

Conduct a full thermography survey of the accessible areas of the tilt plate separator and report on the presence and location of any sand/solid build up within the separator.

by identifying the most suitable locations to collect useful inspection footage and collating the findings to obtain an overall sand/solids quantity.

Solution

ICR mobilised an experienced thermographer to conduct the inspection using the latest infrared thermal imaging technology.

The survey was conducted under normal operating conditions. The production fluids within the separator had a temperature of around 60ºC.

Results & Benefits

- Sand/solid deposits were visible in the infra-red spectrum due to their insulating effect on the surface temperature of the separator wall. The thermal images captured indicated the presence of significant sand/solid deposits in the lower parts of the separator.

- In addition; during the survey it was found that two of the produced water outlets were partially or fully blocked. ICR suggested that these images be used as a baseline to be referenced during repeat inspections scheduled at regular intervals.