Date: July 2023

Client: Drilling Contractor

Location: UK North Sea

Client challenge

A North Sea drilling contractor faced a challenge with rerouting a pipeline system for their drilling package on an offshore rig. They needed a solution that was not only safer but also more cost-effective and time-saving than traditional hot work methods.

What we did

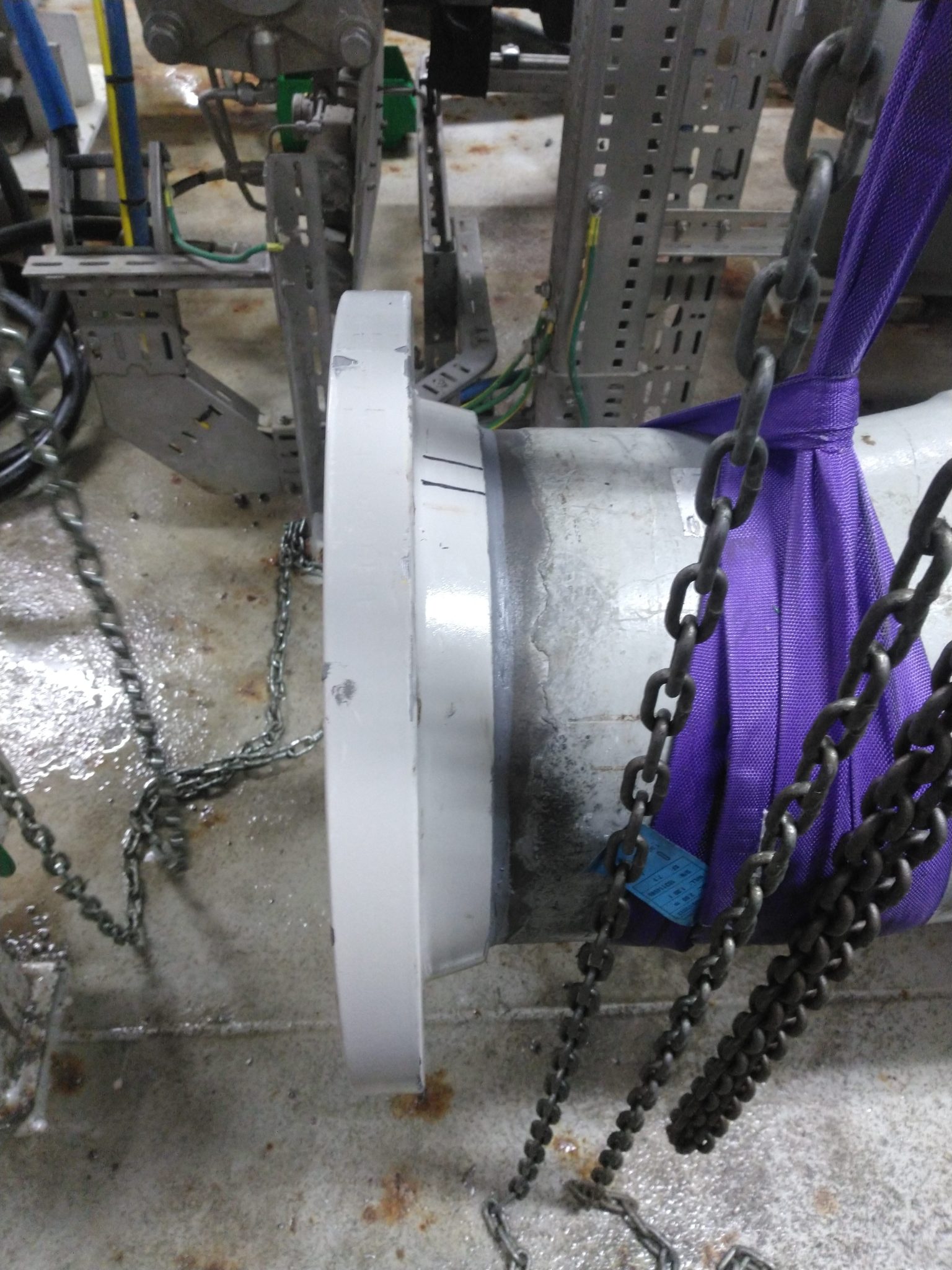

To meet our client’s needs, we obtained approval for a 10” carbon steel 150# Quickflange™ connector, which was ideal for horizontal installation on the asset’s lower deck. Despite facing initial discrepancies with the wall thickness from the listed piping specifications, we included extra match boring equipment in the quotation along with installation tools, testing, and cutting equipment.

We used orbital cutting equipment to cut the pipe and manually prepared the installation area. Wall thickness checks revealed the need for match boring to align the pipe’s wall thickness schedule with the supplied Quickflange™ connector. After completing the match boring, the installation proceeded successfully, passing a hydrostatic leak test.

Results

Our solution resulted in highly positive outcomes for our client. The installation process was significantly faster compared to traditional hot work methods, and the Quickflange™ option provided a simpler, more straightforward installation which was also more cost effective, without the need for permits and habitats. Our technician, proficient in Quickflange™ installation, pipe cutting, and match boring, proved invaluable as only one technician was required, saving space on the client’s onboard asset. Overall, the successful project demonstrated the advantages of our approach in terms of efficiency, safety, and cost-effectiveness.

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation