Quickflange and Weldless Connectors Regulatory Approval: A Testament to Safety

Introduction

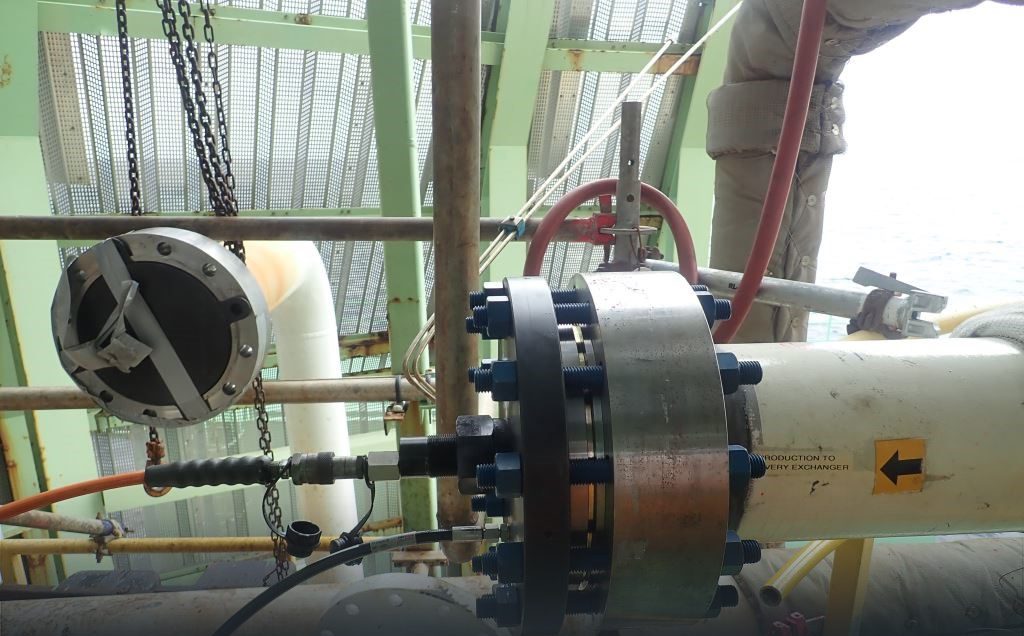

As the energy infrastructure landscape in the United States undergoes transformation, the demand for innovative solutions that enhance efficiency, safety, and regulatory compliance has never been more pronounced. Quickflange weldless connectors offer substantial advantages over traditional welding and replacement methods. This thought leadership piece aims to highlight the benefits of Quickflange weldless connectors in the US market, emphasising regulatory approval and the transformative impact on pressure systems integrity and maintenance.

Regulatory Approval

The USA’s stringent regulatory environment places a premium on safety in all industrial operations, and Quickflange has successfully navigated this. With case-by-case installation approvals from regulatory bodies including Bureau of Safety and Environmental Enforcement (BSEE), attesting to its use as a permanent repair method, these connectors have become a trusted choice for maintenance projects. This regulatory endorsement for connectors up to 14” NPS, provides confidence to operators, ensuring that they are adopting solutions aligned with the highest safety standards.

Mitigating Risks

The inherently safer nature of Quickflange aligns seamlessly with the risk mitigation priorities outlined by regulatory authorities. By eliminating the need for hot work and reducing the potential for accidents associated with traditional welding, these connectors contribute to a safer working environment. This not only safeguards personnel but also protects the integrity of the surrounding infrastructure.

Accelerating Project Timelines

In a sector where project timelines are critical, Quickflange stands out by streamlining installation and maintenance processes. The compact design of these connectors allows for rapid installation, significantly reducing downtime. With regulatory approval validating its reliability, operators can confidently implement the connectors to accelerate project timelines whilst dramatically improving the safety aspect, without compromising on the quality requirements.

Cost-Effective Regulatory Compliance

Quickflange not only fulfils regulatory standards but also provides a cost-effective alternative to traditional welding. The reduced downtime, minimised risk of accidents, and streamlined compliance processes contribute to long-term cost savings. Further to this the reduced labour requirements and costs associated with these connectors contribute to an overall more economical solution, thus allowing operators to allocate resources more strategically, optimising their budget for sustained operations.

Environmental Benefits

Quickflange also offers several environmental benefits compared to traditional welding methods, contributing to a more sustainable approach to maintenance. These benefits include reduced emissions, minimised waste generation, enhanced environmental compliance, and long-term sustainability. These advantages align with the growing global emphasis on sustainable practices.

Conclusion

Quickflange has not only earned its place as an innovative technology but has successfully navigated the regulatory landscape in the USA. As the energy industry continues to evolve, these connectors offer a safer, more efficient, and economically viable alternative to traditional welding methods. By aligning with regulatory standards, operators can not only meet compliance requirements but also pave the way for a future where pressure systems integrity is synonymous with innovation and safety.