Client Offshore gas platform operator

Asset Gas platform

Location Southern North Sea

Result Clamp installed successfully and safeguarding of the service water sytem

Client Challenge

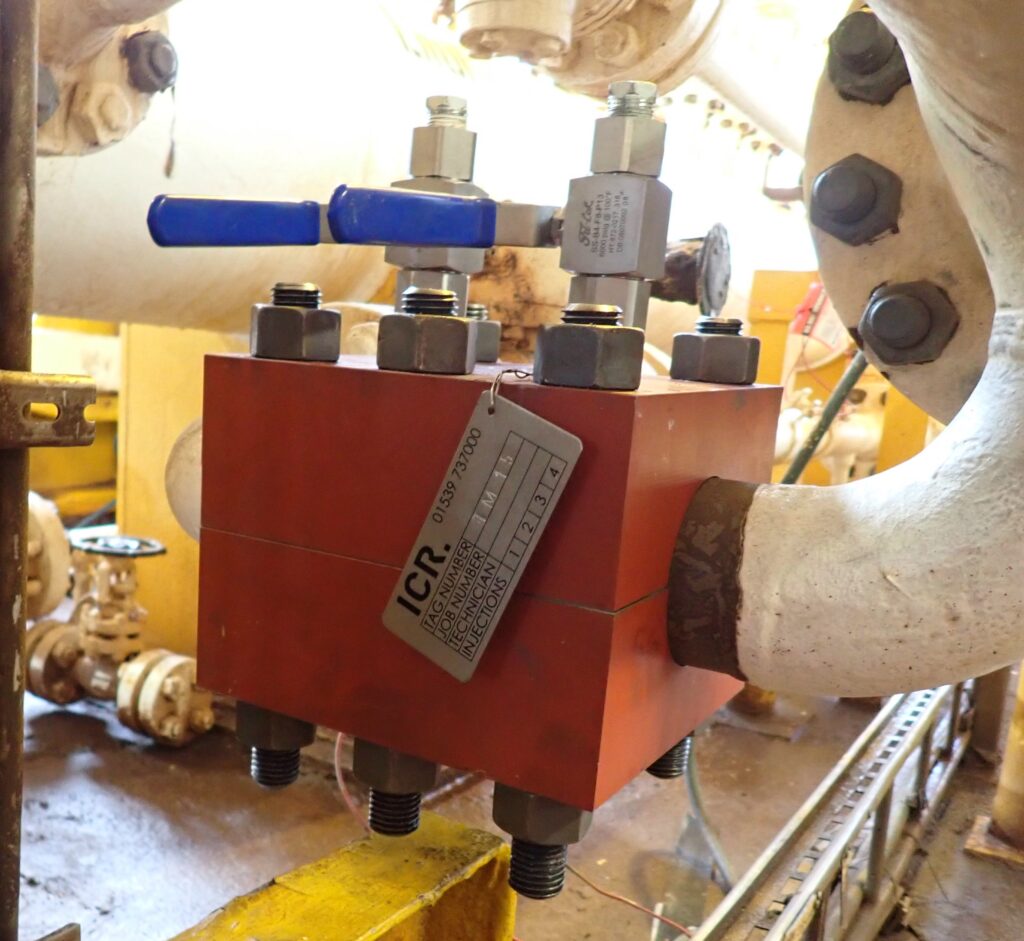

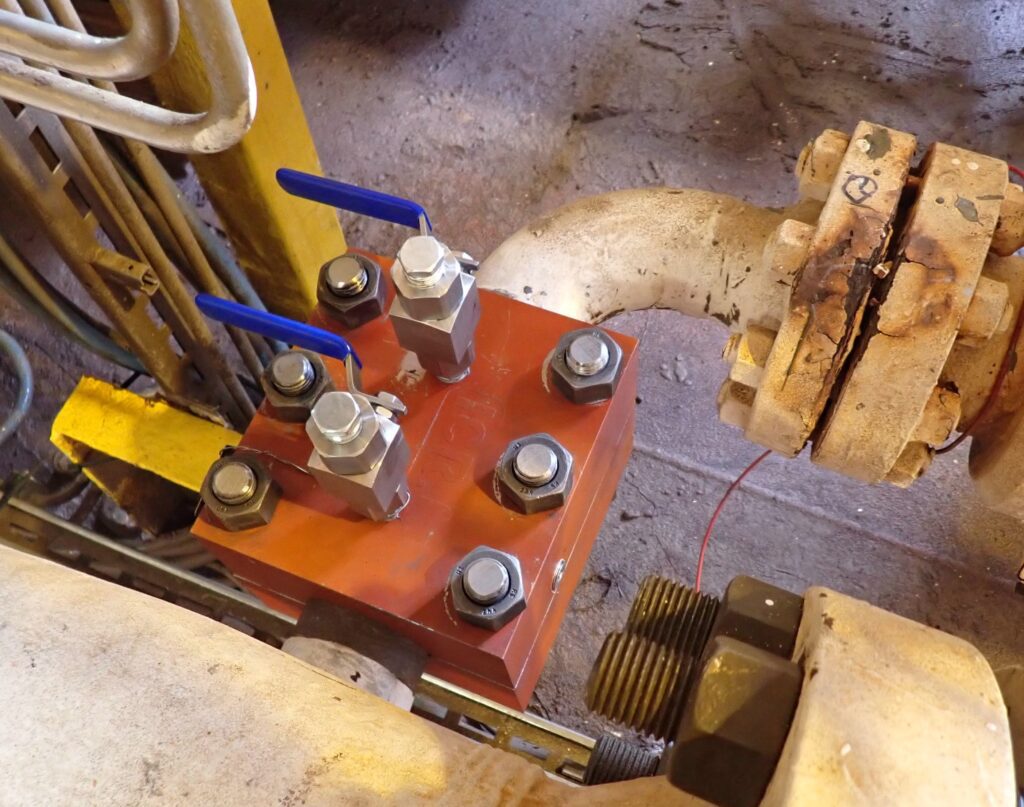

Our client, an offshore gas platform operator, faced a critical challenge involving an on-line leak in a 1½”x ½” tee component that was part of the service water system. This tee had an operating pressure of 60 bar and operated at a temperature of 15°C. Upon inspection, it was discovered that the leak originated from a circumferential crack in the weld connecting the tee, extending onto the pipe. This crack was attributed to vibrations during operation, putting the component at risk of total failure.

What We Did

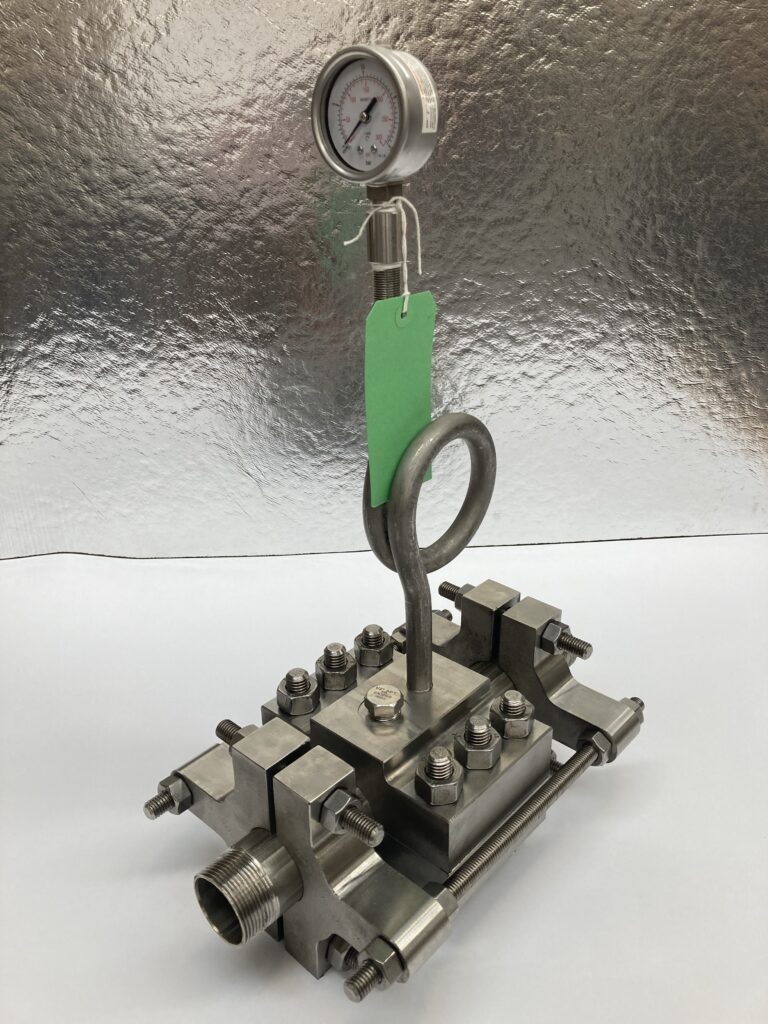

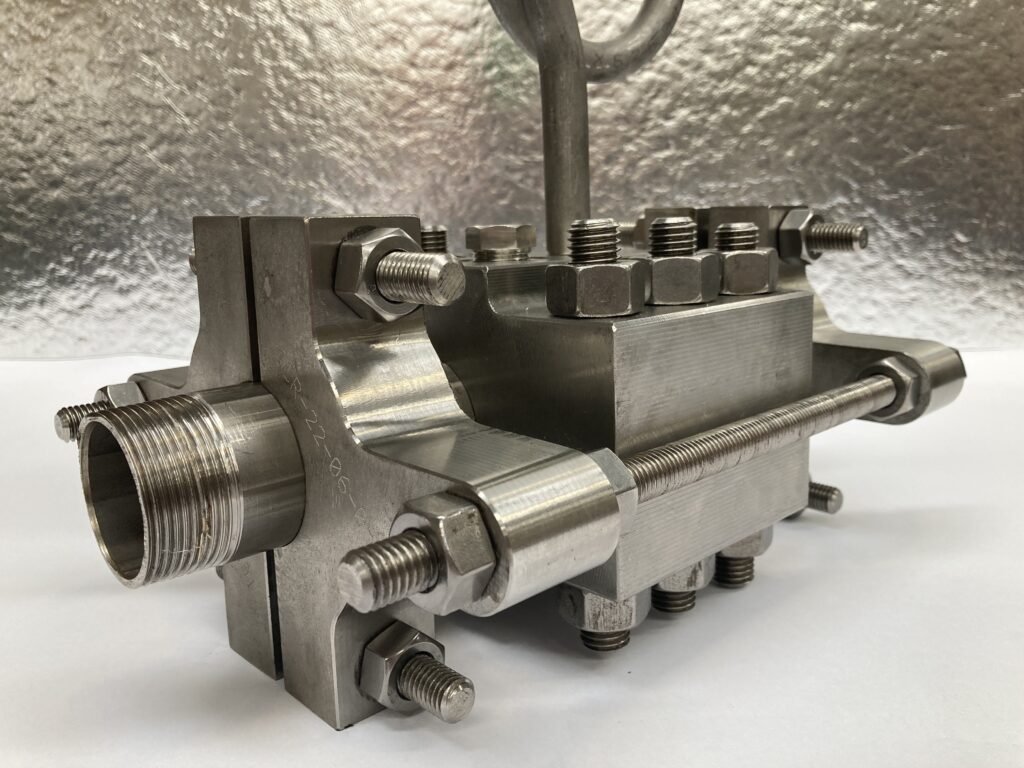

In response to our client’s requirements, we swiftly executed a comprehensive set of solutions, which included the quick mobilisation for defect assessment, the design and engineering of a tailored repair solution in alignment with pipeline design specifications, and the seamless manufacturing and installation of the custom repair clamp. A leak sealing technician was dispatched offshore to conduct a thorough survey of the faulty component and assess the surrounding obstructions, obtaining precise dimensions essential for designing and manufacturing a tailored clamp.

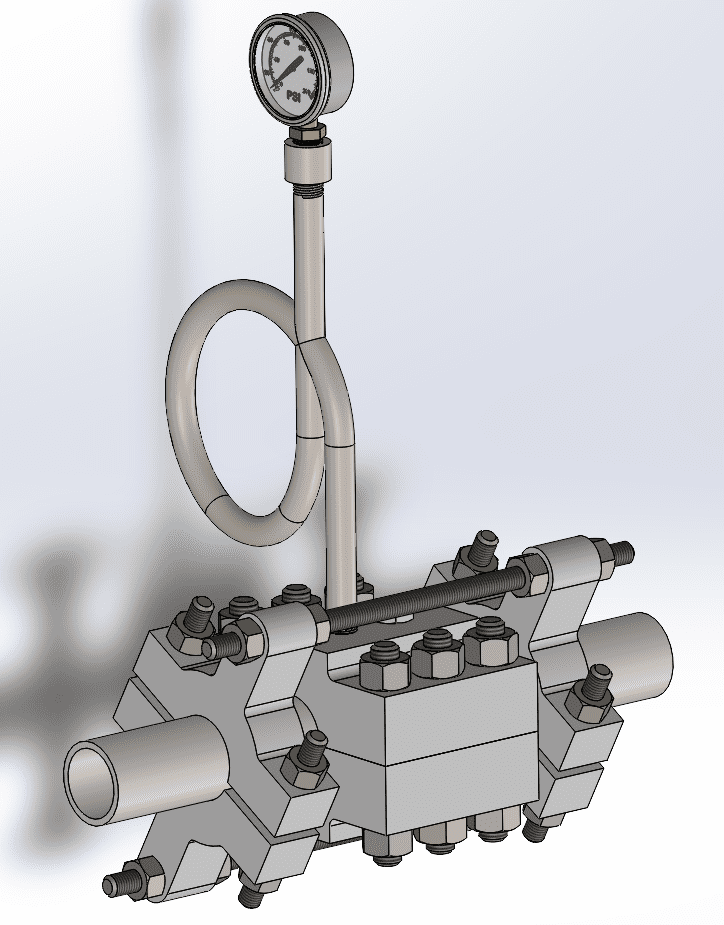

The limited access to the pipe and tight clearance made it challenging to survey and install a conventional clamp. Consequently, bore seals were ruled out during the design phase, and the decision was made to seal the clamp by injecting it with ICR sealing compound. To address our client’s concerns about the compound entering the line during the injection process, our design engineer calculated the internal volume of the clamp and set specific parameters for the compound injection to ensure it did not exceed the safe limit.

Results

The results of our intervention were highly successful. The custom clamp was expertly installed, sealing the leak without any compound entering the line and safeguarding the integrity of the service water system. This swift and efficient resolution eliminated the need for the client to shut down the asset, effectively preventing operational disruptions. Additionally, the success of this interim repair has facilitated the way for the client to plan and execute a permanent solution, bolstering the long-term reliability of the system and mitigating the risk of future leaks.

Date: August 2022

Client: Environmental operator

Location: UK Onshore

Client challenge

Contingency plans are of utmost importance for nuclear power plants in the event of a leak, as they allow for swift and effective response to mitigate potential safety risks and minimize damage. Steam is a vital element of the power generation process, and even small leaks can lead to significant energy losses and safety concerns.

Recently, our team was tasked with developing a contingency plan for a potential 1/2” and 1.1/2 sch 40 stainless steel pipework leak in a nuclear plant. The pipework needed to be re-welded in a tight access area, where ensuring the weld’s integrity posed a significant challenge.

What we did

Our team provided a comprehensive solution to address the 1/2” and 1.1/2 sch 40 stainless steel pipework leak in the nuclear plant. We developed two options:

- A composite repair overwrap.

- Bespoke designed and manufactured leak-sealing split clamps.

To help our client make an informed decision, we conducted a live demonstration where they could see our live leak-sealing facility. Based on our presentation, the client decided to opt for the split leak-sealing clamps.

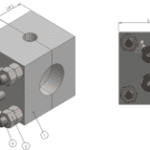

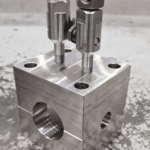

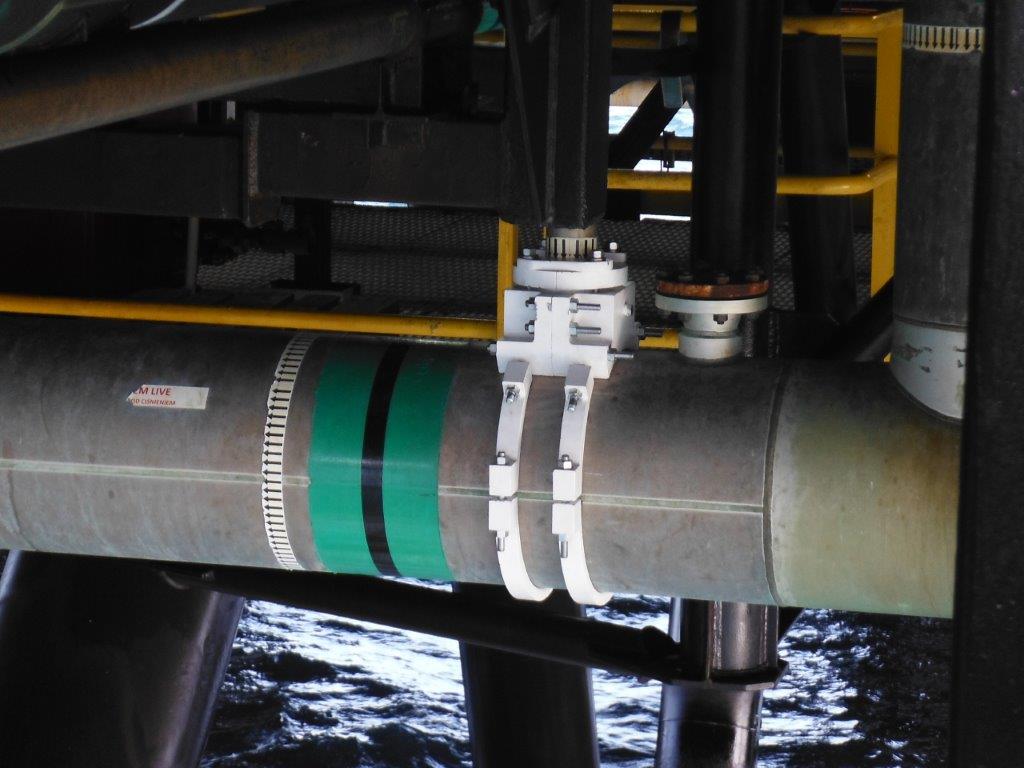

We then embarked on the design, manufacture, and final inspection of five bespoke clamps made from 316 grade stainless steel. To ensure that the clamps were reliable and met all specifications, we held a full week of function testing and factory acceptance at our facility. During this stage, the client and their representatives were present for testing, verification, and sign-off.

Our meticulous approach to the development and testing of the leak-sealing clamps underscores our commitment to delivering high-quality services that ensure safe and efficient operations in nuclear power plants.

Results

We successfully designed and implemented a effective solution which provided a contingency plan for our client. We offer a complete 360º service to our clients in the nuclear market. From initial enquiry to delivery at the site, we work in close collaboration with our clients, ensuring cost-effective contingency measures that are produced right the first time. Our hardware is fully designed, manufactured, and tested at our UK onshore facility, allowing for a seamless process. With a commitment to excellence, ICR is further expanding into the nuclear market.

| Date | Client | Location |

|---|---|---|

| September 2022 | North Sea Transmission Line | UK |

Scope

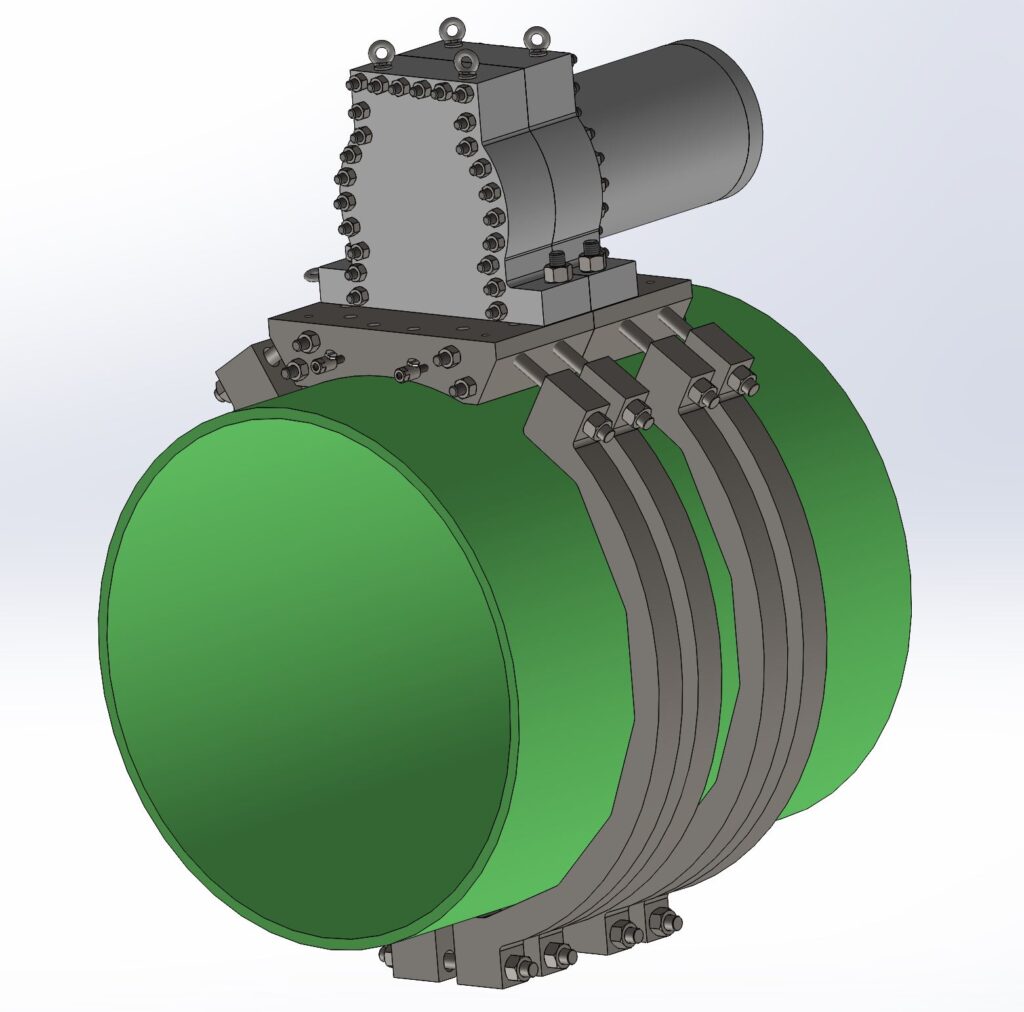

There was potential for a through wall defect on a buried 2” NB valve coming off a 36” NB main import line. With excavation unable to take place prior to delivery of a mechanical clamp solution, the design had to cater for multiple potential valve orientations.

Solution

The mechanical clamp was designed to encapsulate the valve using a saddle and strongback assembly. The multi-part design enabled the clamp to enclose the valve, regardless of what position it was found to be in once excavated. 5-axis machined seal grooves were provided to ensure a reliable seal against the main 36” NB pipe, whilst keeping the size and weight of the solution as low as possible.

Design fully pressure tested in-house prior to shipping to client.

Results & Benefits

- Tested and verified clamp solution delivered to site in time for excavation date.

- Client had confidence a solution was on-site if required during excavation.

| Date | Client | Location |

|---|---|---|

| March 2021 | North Sea Operator | Oil Platform, UKCS |

Scope

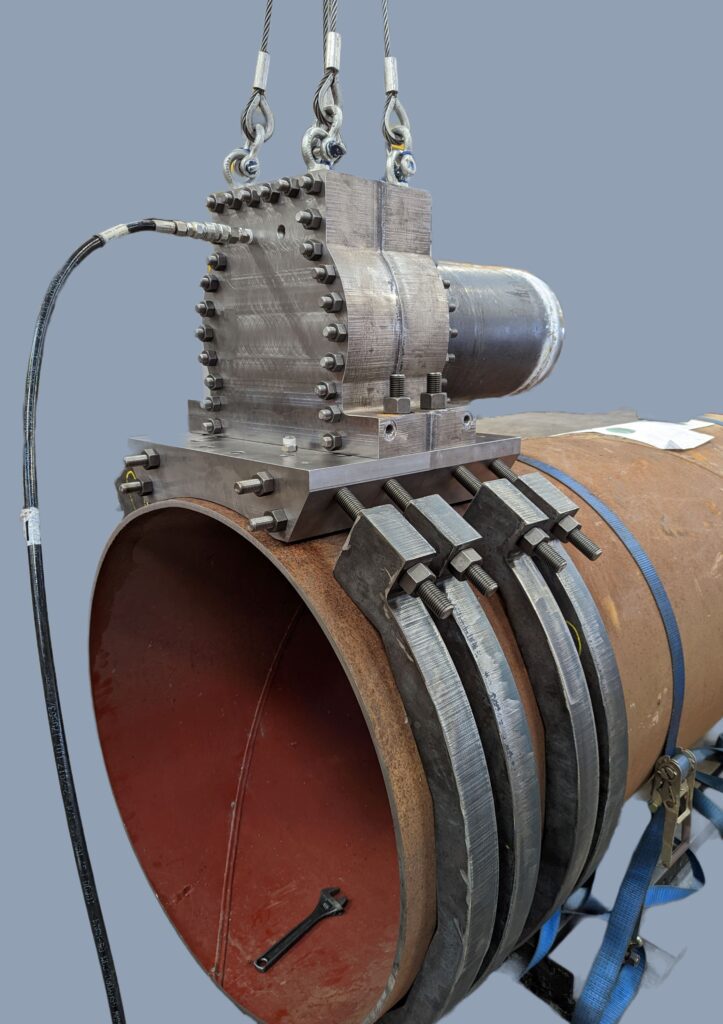

The client approached ICR to seek a solution to encapsulate and seal the leaking defect whilst reinstating integrity to the pipework. The repair involved a 20” NB pipe with a 4” NB branch with a weld defect where the branch pipe joined to the main header causing a seawater leak with the risk of structural failure of the joint.

Solution

We designed and manufactured a mechanical repair clamp to enclose the defective weld. This provided full pressure containment of the leaking line content and reinstated full structural integrity to the pipework.

The main body of the repair clamp is split into two sections, allowing it to be bolted around the defective branch pipe and featured restraints to ensure the 4in NB could not become detached from the 20” header.

The repair utilised an elastomeric seal system, energised around the 20” NB main header pipe, the sealing boundary then runs around the joint face of the split clamp before sealing around the circumference of the branch pipe.

A two-part marine epoxy coating applied externally and internally to the clamp protects the repair from exposure to the marine environment. With the clamp also needing to be installed by ICR rope access specialist, the clamp was designed to keep the weight of the individual components to a minimum with features to ensure the repair could be installed as safely and easily as possible.

Prior to deployment to the platform the clamp was successfully pressure and function tested in-house at ICR.

Results & Benefits

- Client line integrity reinstated, leaking product fully enclosed

- Cost-effective, long-term repair solution

- Client has avoided the need to shutdown in order to repair the defective pipework

- Finished ahead of schedule meaning limited COVID restricted bed space could be freed up for the client

| Date | Client | Location |

|---|---|---|

| May 2021 | North Sea Oil Platform | UKCS |

Scope

A through wall defect with a hydrocarbon leak on a 3 in NB pipe on an offshore platform export piping system causing a shut down.

The client approached ICR for a solution to encapsulate and seal the leaking defect.

Design parameters

Process medium: Hydrocarbons

Design Pressure: 138 bar

Design Temperature: 120°C

Solution

A composite repair was considered and discounted in favour of a mechanical repair clamp to enclose the defect. The repair clamp was designed to provide full pressure containment of the leaking line contents.

The repair clamp utilised an single elastomeric seal system energised around pipe, the sealing boundary then runs around the joint face of the split clamp sealing around the circumference of the pipe. The main cavity of the clamp was injected with a two part high density flexible sealant.

Prior to deployment to the platform, the clamp was successfully pressure and function tested in-house at ICR.

The repair clamp was manufactured and delivered to the client in 4 days from the award of contract. ICR technicians were mobilised to carry out the installation and testing, the scope completed in 7 days from contract award, several days ahead of the clients original target.

Results & Benefits

- Customer line integrity reinstated, leaking product fully enclosed

- Installation able to start up without the additional delays associated with a hot work repair

- Finished ahead of schedule