Scope

ICR was approached by the client to replace their existing ferric sulphate injection package. The current pumps were oversized for the process requirements resulting in high pulsation and vibration due to the short stroke and fast motor frequency required to meet the flow needs. ICR conducted an engineering site survey, working closely with the client to find the best solution.

ICR delivered a fully automated, containerised ferric sulphate injection package consisting of 6 electric drive, VFD controlled injection pumps (4 duty and 2 standby).

Solution

Ferric Sulphate Injection Package consisting of the following:

- Fully automated ferric sulphate injection package, with required hardware to allow remote monitoring, control and operation via onsite control system

- Package integrated into modified 20-foot shipping container, housing all chemical injection, electrical, and ancillary equipment.

- Container internals lined out with 12mm thick “Aqua-panels”, chemical resistant non-slip floor and integral stainless-steel bund

- 3 Polypropylene injection pump cabinets (2 duty and 1 standby) c/w Perspex sliding doors

- Each cabinet contains 2 Milton Roy MAXROY, VFD controlled, electrically driven pumps with each pump being capable of injecting 407.5 litres per hour

- Package control panel with integral HMI touch screen and local VFD touch pads

- Emergency eye bath station

Results & Benefits

- Fully assembled package delivered to site, minimising hook-up and onsite work requirements

- Bespoke package designed to meet client specifications and process parameters

- Fully automated to be integrated into on-site control systems

Scope

To supply an electric drive Pour Point Depressant injection package. Injection Rate: 0-1800 litres per hour Duty Process Pressure: 13.8 barg Fluid Viscosity: Up to 600 cP Ambient Temperature: -15 to +30 °C Skid ATEX Classification: Zone 2 IIA T3 Power Requirement: 440V 3ph 50hz Chemical reservoir: Tanker (by others)

Required Injection Rate: 0-1800 litres per hour

Duty Process Pressure: 13.8 barg

Fluid Viscosity: Up to 600 cP

Ambient Temperature: -15°C to 30°C

Skid ATEX Classification: Zone 2 IIA T3

Power Requirement: 440V 3ph 50hz

Chemical reservoir: Tanker (by others)

Solution

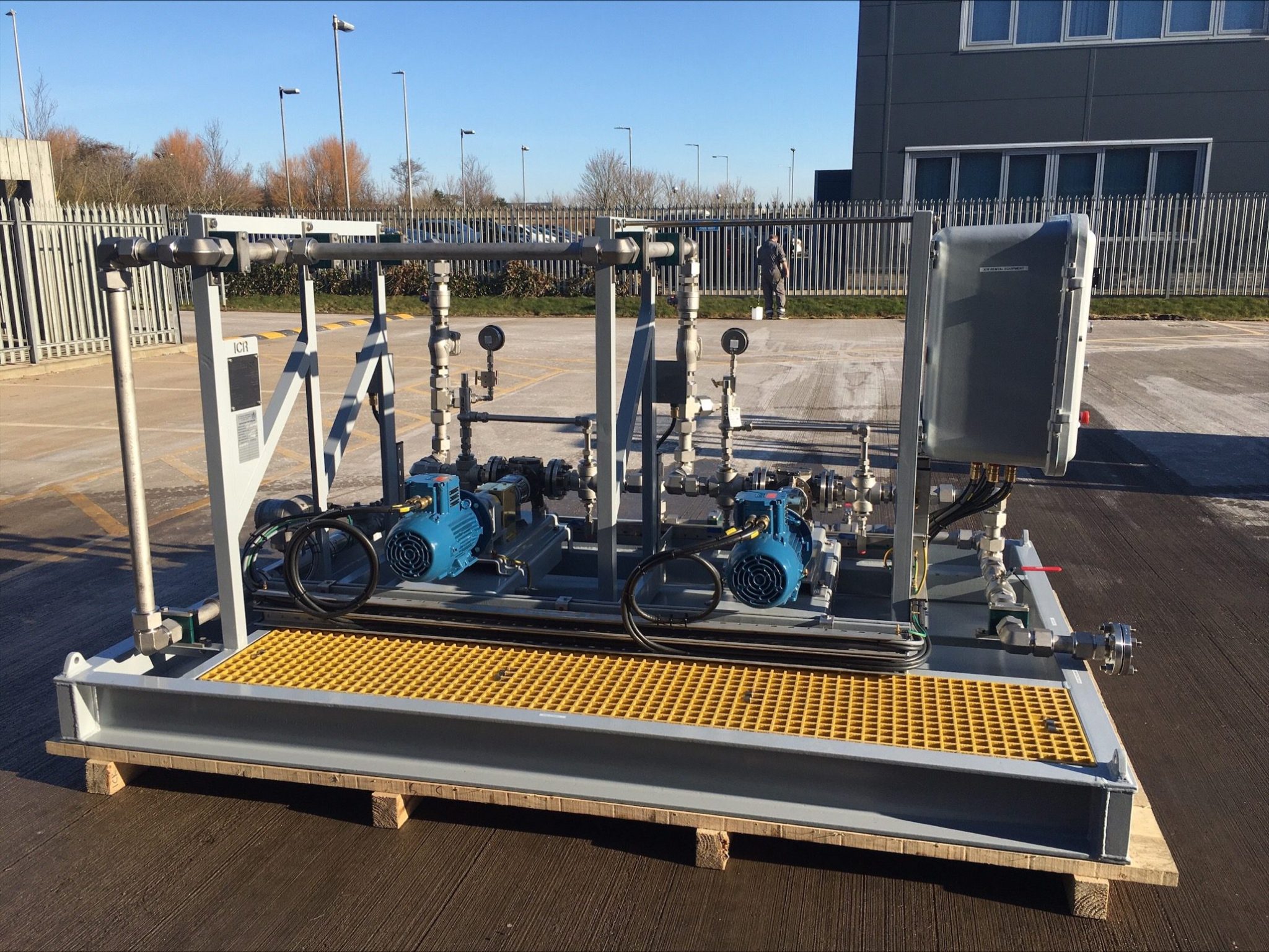

- ICR proposed SPX Flow Internal Gear Pumps in a duty/standby arrangement c/w variable speed electric motors

- Motor speed was locally controlled by a skid-mounted Ex d control panel

- Coriolis Flowmeter power supplied via the control panel

- On-skid equipment earthing provided along with On-skid cable support system

- Package was installed on a painted carbon-steel base frame c/w integral sloping drop tray with drain valve, certified lifting points, sling set and spreader lift beam

- Tubing, fittings, valves and components supplied in 316 stainless steel

- Discharge manifold fitted with dissimilar check valves for increased reliability

Results & Benefits

- Pumps capable of pumping viscous fluids at the required flowrate

- Bespoke control system configured to accept incoming power from client distribution board Overpressure safety built into design with discharge pressure relief valves

- Stable discharge flow and pressure through use of pulsation dampeners

- Real time flow rates and cumulative flow displayed locally on Coriolis flowmeter

Scope

ICR was approached by a major North Sea operator to design and manufacture a bespoke, permanent Injection Pump Package for dosing of Sodium Hypochlorite to four seawater lift pump caissons on a UKCS Platform.

Solution

ICR supplied a package with 4‐off air driven, API-675 dosing pumps for Sodium Hypochlorite dosing to respective seawater lift pump caissons. Each pump was served by a dedicated Solenoid Valve (SOV) to start / stop pump on signal from platform Integrated Control and Safety System (ICSS).

The package included a back‐pressure control valve on each pump discharge line to prevent syphoning of the sodium hypochlorite solution from existing hypochlorite storage tank.

The package comprised of the following:

- 1 of painted carbon steel base frame c/w titanium drip tray

- 4 off (4 off duty) Williams Milton Roy CRLD200-TI-TFE air driven hydraulic actuated diaphragm chemical injection pumps

- Process tubing, fittings, and wetted metallic parts supplied in Grade 2 Titanium.

- Suction manifold incorporating all valves, suction filter for each pump and common calibration pot

- Discharge lines for each pump incorporating a pressure relief valve (PRV) routed to pump suction, pressure indicator, back pressure control valve and isolation valve

- Air manifold incorporating isolation valves, filters, and regulator

- Pneumatic installation on the package incorporating 4‐off SOVs (each supplied with manual override) on each pump supply (for individual pump start/stop control)

- Instrument junction box, located at skid edge to facilitate connection of client cabling

Results & Benefits

- Fully assembled package delivered to site, minimising hook-up, and onsite work requirements

- Bespoke package designed, built and fully tested to meet client specifications and process parameters.