Date: August 2022

Client: Environmental operator

Location: UK Onshore

Client challenge

Contingency plans are of utmost importance for nuclear power plants in the event of a leak, as they allow for swift and effective response to mitigate potential safety risks and minimize damage. Steam is a vital element of the power generation process, and even small leaks can lead to significant energy losses and safety concerns.

Recently, our team was tasked with developing a contingency plan for a potential 1/2” and 1.1/2 sch 40 stainless steel pipework leak in a nuclear plant. The pipework needed to be re-welded in a tight access area, where ensuring the weld’s integrity posed a significant challenge.

What we did

Our team provided a comprehensive solution to address the 1/2” and 1.1/2 sch 40 stainless steel pipework leak in the nuclear plant. We developed two options:

- A composite repair overwrap.

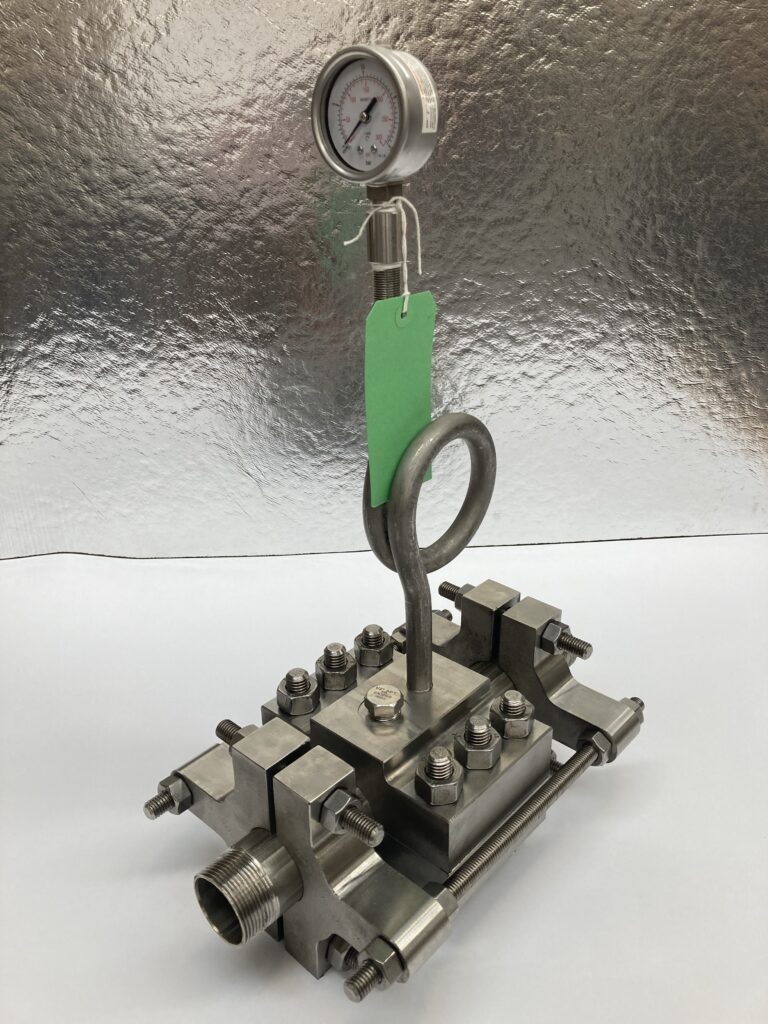

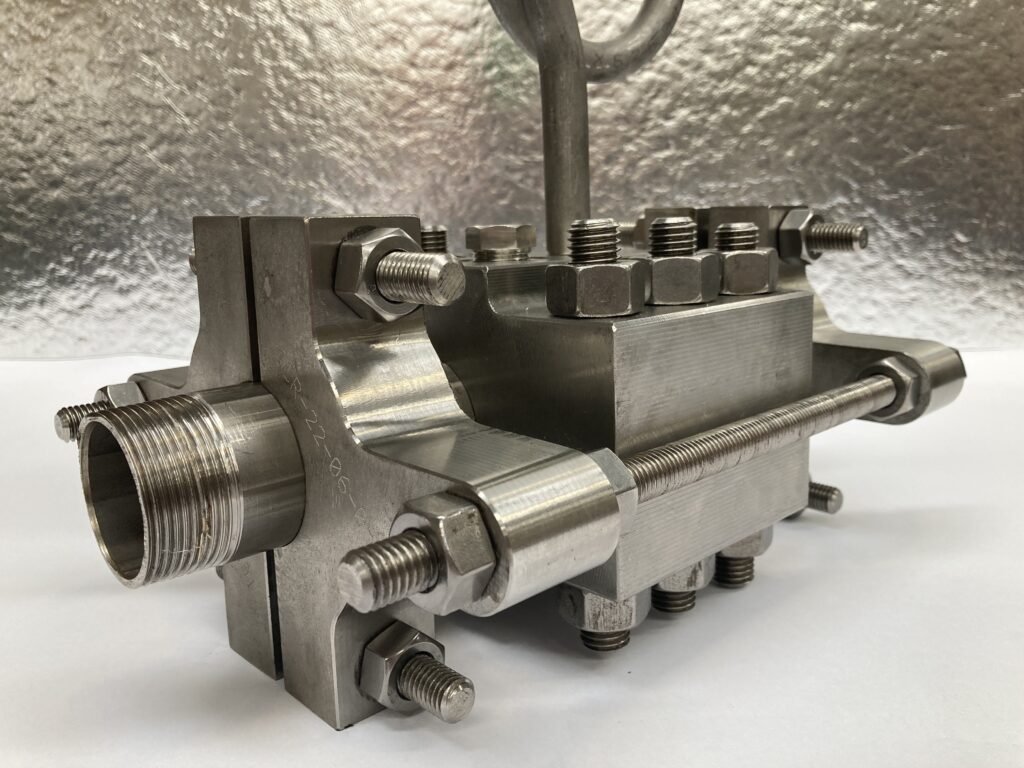

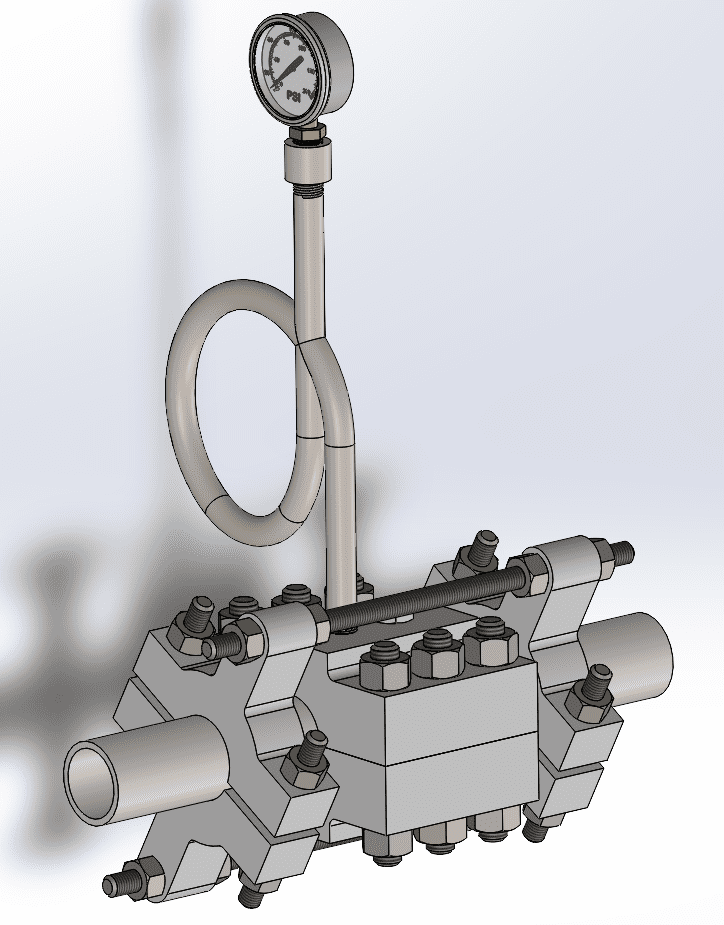

- Bespoke designed and manufactured leak-sealing split clamps.

To help our client make an informed decision, we conducted a live demonstration where they could see our live leak-sealing facility. Based on our presentation, the client decided to opt for the split leak-sealing clamps.

We then embarked on the design, manufacture, and final inspection of five bespoke clamps made from 316 grade stainless steel. To ensure that the clamps were reliable and met all specifications, we held a full week of function testing and factory acceptance at our facility. During this stage, the client and their representatives were present for testing, verification, and sign-off.

Our meticulous approach to the development and testing of the leak-sealing clamps underscores our commitment to delivering high-quality services that ensure safe and efficient operations in nuclear power plants.

Results

We successfully designed and implemented a effective solution which provided a contingency plan for our client. We offer a complete 360º service to our clients in the nuclear market. From initial enquiry to delivery at the site, we work in close collaboration with our clients, ensuring cost-effective contingency measures that are produced right the first time. Our hardware is fully designed, manufactured, and tested at our UK onshore facility, allowing for a seamless process. With a commitment to excellence, ICR is further expanding into the nuclear market.

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation