Scope

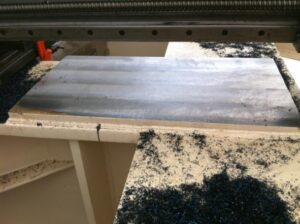

The power generation module contained three bearing pads welded to steel work and used to provide a level footprint for mounting the power generating unit within the module. The pads had been welded to the steelwork and were not level to either the module datum or each other. Surveying services had been used to provide flatness datums and material removal sizes for setting up the machining equipment. The machining equipment had to be able to span each plate and be clamped rather than welded to reduce requirement for hot work.

Solution

ICR technicians – together with a suitable size gantry mill – were mobilised to carry out this operation. The milling machine was set up to the survey datums and material was machined from the pads to bring them flat to the module datum and at the same level as each other.

Results & Benefits

- Following the machining operation an additional survey was carried out which confirmed that the pads were well within the required tolerance

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation