Client Offshore gas platform operator

Asset Gas platform

Location Southern North Sea

Result Clamp installed successfully and safeguarding of the service water sytem

Client Challenge

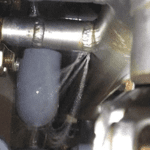

Our client, an offshore gas platform operator, faced a critical challenge involving an on-line leak in a 1½”x ½” tee component that was part of the service water system. This tee had an operating pressure of 60 bar and operated at a temperature of 15°C. Upon inspection, it was discovered that the leak originated from a circumferential crack in the weld connecting the tee, extending onto the pipe. This crack was attributed to vibrations during operation, putting the component at risk of total failure.

What We Did

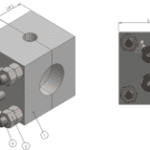

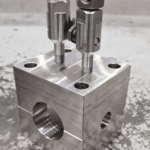

In response to our client’s requirements, we swiftly executed a comprehensive set of solutions, which included the quick mobilisation for defect assessment, the design and engineering of a tailored repair solution in alignment with pipeline design specifications, and the seamless manufacturing and installation of the custom repair clamp. A leak sealing technician was dispatched offshore to conduct a thorough survey of the faulty component and assess the surrounding obstructions, obtaining precise dimensions essential for designing and manufacturing a tailored clamp.

The limited access to the pipe and tight clearance made it challenging to survey and install a conventional clamp. Consequently, bore seals were ruled out during the design phase, and the decision was made to seal the clamp by injecting it with ICR sealing compound. To address our client’s concerns about the compound entering the line during the injection process, our design engineer calculated the internal volume of the clamp and set specific parameters for the compound injection to ensure it did not exceed the safe limit.

Results

The results of our intervention were highly successful. The custom clamp was expertly installed, sealing the leak without any compound entering the line and safeguarding the integrity of the service water system. This swift and efficient resolution eliminated the need for the client to shut down the asset, effectively preventing operational disruptions. Additionally, the success of this interim repair has facilitated the way for the client to plan and execute a permanent solution, bolstering the long-term reliability of the system and mitigating the risk of future leaks.

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation