| Date | Client | Location |

|---|---|---|

| August 2019 | Major North Sea Operator | Onshore Aberdeen |

Scope

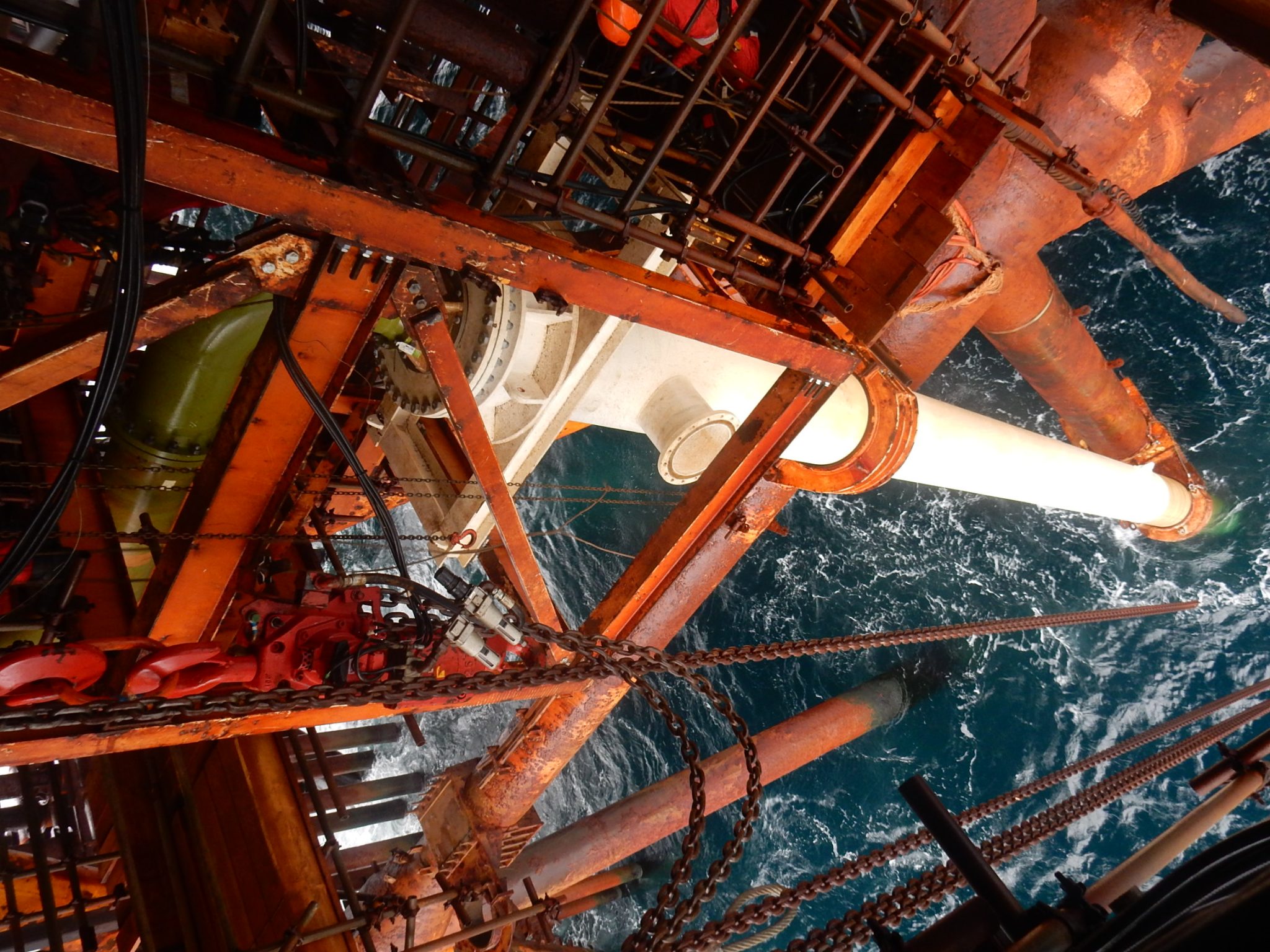

ICR were engaged to provide a engineered composite repair solution on a produced water caisson prior to installation offshore. The previous caisson was corroded due to wave action causing thermal cycling.

Solution

Two new sections of a 12” caisson were fabricated and sprayed with an internal coating prior to ICR applying the composite solution. It was a design requirement that surface preparation to Sa2.5 and was achieved prior to the application of 4 layers of Technowrap™ 2K using HT (High Teemperature) resin.

These were then welded together and an angular profile of 45μ was achieved using bristle blasters. A composite wrap was then applied to cover the welded section. Heat blankets were used througout the process to assist curing.

| Design Temperature | 100°C |

| Design Pressure | 2.5bar |

| Material Grade | Super Duplex |

| Surface Preparation | Sa2.5 |

The change in temperature was taken into consideration by derating the allowable strains in line with ISO 24817.

Results & Benefits

- ICR technicians worked day and night for a total of 7 days to complete the repair

- A repair lifetime of 20 years was given

- The solution will prevent future corrosion due to thermal cycling, maintaining the integrity of the structure

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation