Client: Operator

Asset: Offshore asset

Location: Southern North Sea

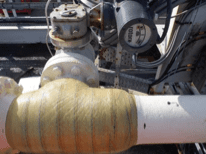

Result: The INSONO™ inspection was completed to assess the integrity of wraps applied to a series of off-takes.

Client challenge

Our client, a energy operator, faced the challenge of ensuring the integrity and reliability of their composite wrap processes. They needed a solution that would deliver confidence and assurance in Fitness for Service (FFS)/Risk-Based Inspection (RBI) schemes. The specific challenge was to locate, measure, record, and monitor anomalies associated with both baseline/new wrap surveys and in situ wraps. It is important to identify any anomalies associated with any composite repair and monitor them over time to ensure continued safe operation and minimise risk to the overall infrastructure.

What we did

To address the client’s challenge, we implemented our non-intrusive technique INSONO™ into the FFS/RBI schemes. INSONO™ utilises a non-intrusive (NII) examination technique incorporating low-frequency sound waves to assess the internal body of the composite wrap and substrate. This method locates, quantifies, and records anomalies that could compromise the suitability for service.

The versatility of INSONO™ as a proven non-intrusive technique made it particularly suitable for inspecting wraps in challenging and unconventional areas. This included leaks or damaged areas that tend to arise during production, as well as bends, valves, multiple pipework connections, headers, pipe racks, vessels, and various structural locations. The adaptability enabled it to address the client’s specific concerns and requirements, showcasing its effectiveness in diverse configurations.

Our inspection established a baseline reference for future wrap inspections as part of the Written Scheme of Examination/ Risk-Based Inspection (WSE/RBI) process, ensuring continued service in line with RBI/WSE standards.

Results

The incorporation of INSONO™ as an inspection tool proved to be highly successful. It provided a robust solution for locating, measuring, recording, and monitoring anomalies associated with wrap repairs and substrates. This method demonstrated its efficacy in both baseline, new wrap surveys and current in situ wraps, offering repeatability for ongoing assessments. Our client gained confidence and assurance in the composite wrap process, knowing that potential issues affecting integrity and life cycle were systematically identified and addressed.

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation