| Date | Client | Location |

|---|---|---|

| March 2021 | North Sea Operator | Oil Platform, UKCS |

Scope

The client approached ICR to seek a solution to encapsulate and seal the leaking defect whilst reinstating integrity to the pipework. The repair involved a 20” NB pipe with a 4” NB branch with a weld defect where the branch pipe joined to the main header causing a seawater leak with the risk of structural failure of the joint.

Solution

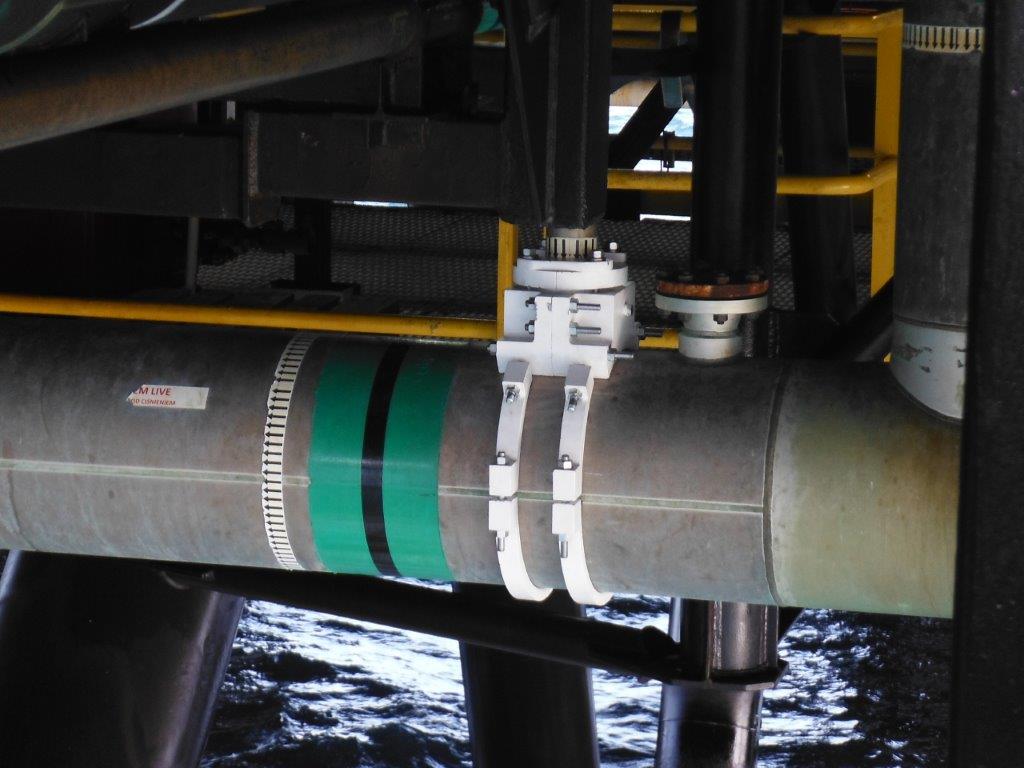

We designed and manufactured a mechanical repair clamp to enclose the defective weld. This provided full pressure containment of the leaking line content and reinstated full structural integrity to the pipework.

The main body of the repair clamp is split into two sections, allowing it to be bolted around the defective branch pipe and featured restraints to ensure the 4in NB could not become detached from the 20” header.

The repair utilised an elastomeric seal system, energised around the 20” NB main header pipe, the sealing boundary then runs around the joint face of the split clamp before sealing around the circumference of the branch pipe.

A two-part marine epoxy coating applied externally and internally to the clamp protects the repair from exposure to the marine environment. With the clamp also needing to be installed by ICR rope access specialist, the clamp was designed to keep the weight of the individual components to a minimum with features to ensure the repair could be installed as safely and easily as possible.

Prior to deployment to the platform the clamp was successfully pressure and function tested in-house at ICR.

Results & Benefits

- Client line integrity reinstated, leaking product fully enclosed

- Cost-effective, long-term repair solution

- Client has avoided the need to shutdown in order to repair the defective pipework

- Finished ahead of schedule meaning limited COVID restricted bed space could be freed up for the client

Featured articles

University of life stands Govan-raised engineer in good stead

LR and UKAS boost for ICR Group’s INSONO innovation