Delivering specialist maintenance, integrity and inspection solutions in Australasia

Latest Case Study: Technowrap™ Corroded Crane Cab Restoration – Western Australia

Latest Case Study: Resolving Corrosion for Australian Energy Operator

Delivering specialist maintenance, integrity and inspection solutions in Australasia

Established in 2012, IC Integrity is a joint venture between ICR and IAS (now part of UGL). Combining internationally-recognised integrity solutions with local expertise, IC Integrity continuously delivers successful projects across multiple sectors, including oil and gas, power, and process industries.

Headquartered in Canning Vale, Western Australia, IC Integrity provides Australasian businesses with a range of cost-effective technologies, including Technowrap™ composite repairs and ICR’s unique composite repair inspection technology.

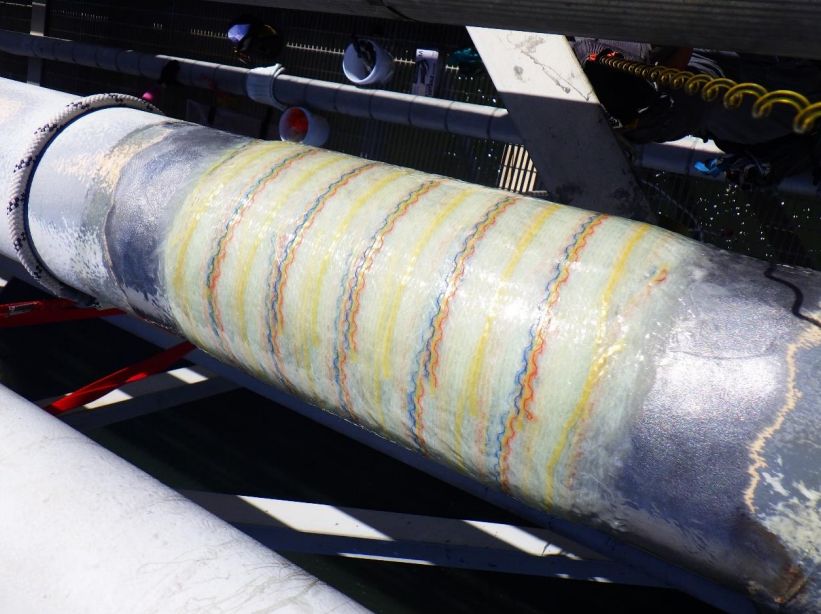

Technowrap™ composite repairs

This composite repair technology is a long-term, cost-effective alternative to steel replacement and can be applied to live targeted areas without requiring a shutdown. Tested and qualified to ISO 24817 and ASME PCC-2, Technowrap™ can address various defects, including internal and external corrosion and through-wall defects. More than 50,000 successful repairs have already been completed using this technology on pipework, pipelines, decks, and more.

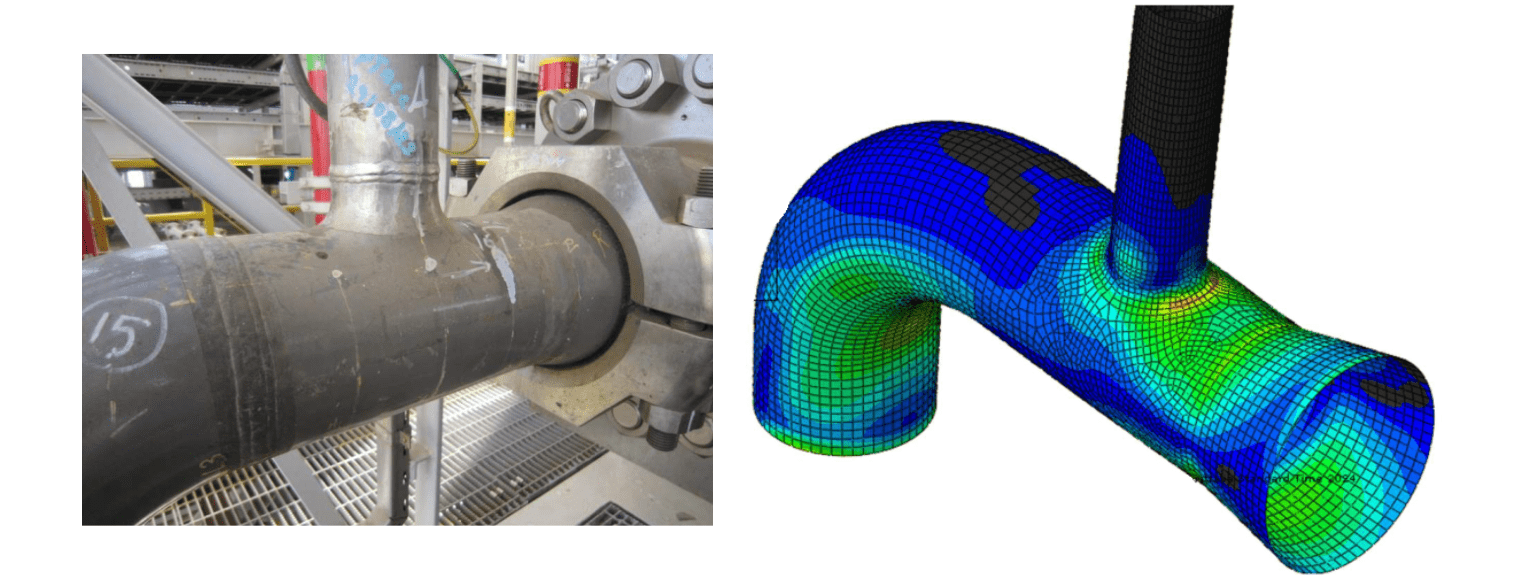

Additional service: Complex composite engineering

While most composite repairs can be designed within existing code provisions such as ISO 24817 and ASME PCC-2, IC Integrity enhances client confidence by providing detailed analyses that assess both bond line performance and through-thickness laminate behaviour. This is particularly beneficial when complex load cases or repair geometries require a more in-depth evaluation to demonstrate composite strength. Our approach ensures an optimised design that accounts for substrate strength contributions while minimising overall repair thickness and installation time.

Our team has extensive experience collaborating with client-nominated engineering consultancies, third-party approval bodies, and classification societies, helping to ensure these complex projects run as efficiently as possible.

Composite repair inspection

Our technology utilises an acoustic inspection method that employs bespoke pitch-and-catch, resonance, and mechanical impedance analysis probes to detect and size anomalies within composite repairs. Inspections conducted with this portable, handheld equipment can determine whether the repair is fit for purpose or if a remedial repair is required. Our inspection capabilities have been independently verified by Lloyds Register, UKAS and TWI.

Examples of our work

Our team

IC Integrity is led by an experienced team committed to delivering cost-effective and time-efficient projects for our customers across Australasia. With a team of local, experienced technicians on hand, we’re ready to support your business’s asset integrity needs. Please reach out to us today to learn more about our service offerings or to make an inquiry. Alternatively, complete the form below.