Challenges

- Multiple repairs with different geometries

Benefits

- Cost-effective

- Quick installation

- No hot work

- Completely engineered repair

Scope

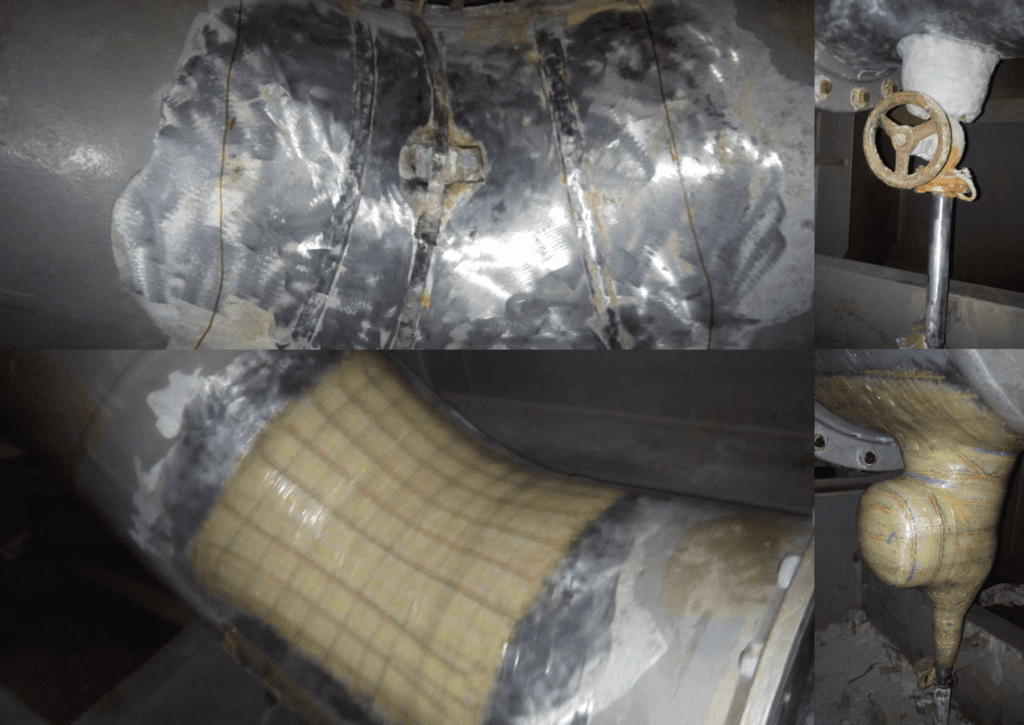

A multinational oil and gas company engaged ICR to deliver multiple composite repairs aboard one of its major LNG carriers. Located in Doha – Qatar, the tanker featured carbon steel ballast water lines that had developed through-wall defects as a result of corrosion.

After assessing the asset condition, including defect dimensions, pipe geometry, operating pressure, temperature and coating condition, ICR engineered Technowrap™ composite repair solutions to restore the structural integrity of the ballast water system with a design life of 10 years.

Once the repair design was approved, we quickly mobilised personnel and materials to the vessel.

Solution

The first repair location, situated on a valve within the ballast line, required full encapsulation using eight layers of our Technowrap™ composite system incorporating our High Ambient (HA) resin.

The second repair location on the main line required an eight-layer patch repair to address a through-wall defect on a 24″ carbon steel section.

Following surface preparation at each defect location, our technicians systematically applied the composite layers according to the engineered design. Final QA/QC checks, including visual inspection and hardness testing, were performed to verify the quality and integrity of each repair before demobilisation.

Results

Despite the need for two different repair types, complete valve encapsulation and a patch repair, ICR’s team successfully engineered, mobilised, and delivered the repairs within the customer’s required timeframe and budget.

A seamless project from start to finish, ICR has since continued to support this client with further composite repairs across its major assets.

Contact Us

This is just one of the composite repair scopes that ICR has delivered in the Middle East. To find out more, or to get in touch with our team, please click here.

Challenges

- Challenging geometry

Benefits

- Cost-effective

- Quick installation

- No hot work

- Completely engineered repair

Scope

An international shipping company contacted ICR to provide an engineered composite repair solution for its specialised reefer vessel, which was recently operating in Netherlands.

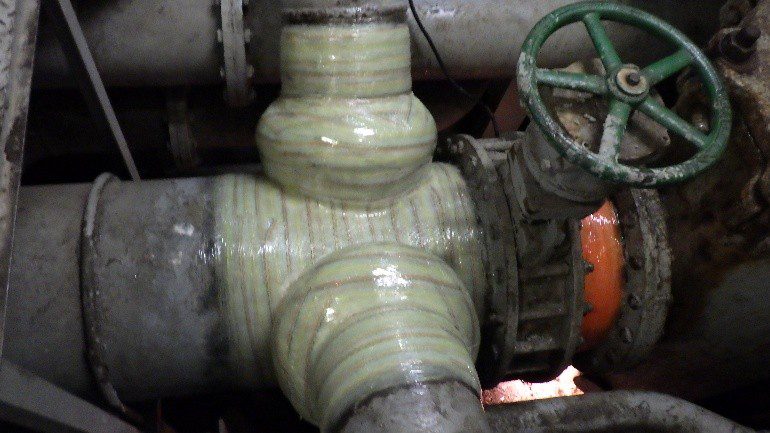

The vessel featured a 10” carbon steel cross-over pipe located in the engine room floorplate, which was suffering from a through-wall defect caused by internal corrosion.

ICR engineered a single composite repair solution to restore the integrity of the line, designed to provide a service life of 10 years.

Solution

After reviewing the conditions of the cross-over pipe, including defect size, tee geometry, temperature, pressure, and other factors, our team determined that 14 layers of our 2K cloth and Low Temperature (LT) resin system would effectively restore the line.

Personnel and materials were quickly mobilised to the site, and surface preparation was completed via bristle blasting.

Our technicians then applied the layers before completing final QA/QC checks to verify the integrity of the cross-over pipe.

Results

The defect was fully resolved, achieving the targeted 10-year design life. This repair provided a quick, cost-effective solution and showcased the capabilities of Technowrap™, even despite the challenging geometry.

Contact Us

If you would like to learn more about Technowrap™ Composite Repairs and our capabilities in the Netherlands, please contact our Key Account Manager, Ryan Crabb (ryan.crabb@icr-world.com).

Challenges

- Multiple significant defects

Benefits

- Cost-effective

- Quick installation

- No hot work

- Completely engineered repairs

Scope

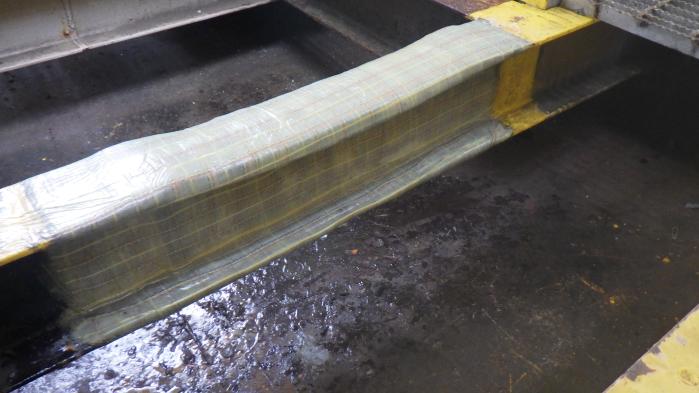

A leading multinational energy and petrochemical company engaged ICR to restore several corroded I-beams using Technowrap™ engineered composite repairs.

Located offshore Malaysia, the asset featured six carbon steel I-beams suffering from corrosion, with an average remaining steel thickness ranging from 0.1 mm to 1 mm.

The customer requested that ICR restore the load bearing capacity of the I-beams with engineered repairs designed for a 20-year service life.

Solution

After analysing the corroded I-beams, ICR’s technical team determined that a Technowrap™ solution comprising two to four layers of 2K glass fibre cloth with High Ambient (HA) resin would effectively repair each defect and ensure a 20-year design life.

In conjunction with a local partner, highly experienced technicians and materials were mobilised to the asset to install the engineered repairs which were completed with minimal disruption, ensuring no production downtime.

Final QA/QC inspections were completed on each repair, verifying the quality of every Technowrap™ installation.

Results

This project highlighted the speed, versatility, and reliability of Technowrap™. Despite significant defect sizes, all repairs were successfully restored to achieve a 20-year design life.

As a safer and more cost-effective alternative to steel replacement, we look forward to helping more customers across Asia adopt this technology in their operations.

Contact Us

If you have a question about this case study, or would like to enquire about using Technowrap™ in Malaysia, then please contact our International Business Development Manager, Iain Masson (iain.masson@icr-world.com).

Challenges

- 18-ft long shell section repair

- High-temperature repair

Benefits

- Cost-effective alternative

- Quick installation

- No hot work

Scope

A major chemical company on the Southeast Texas Gulf Coast successfully completed a 30” exchanger repair using its preferred maintenance contractor, who are trained in Technowrap™ composite repairs.

The 18-ft-long shell section of the carbon steel exchanger, which operates at 340°F, features two longitudinal seam welds experiencing preferential weld attacks. This resulted in internal corrosion and several through-wall defects.

Solution

During the repair, the exchanger was taken offline. Due to the flammable-area classification, Technowrap™ proved to be an optimal solution for restoring line integrity without requiring any hot work.

ICR’s team designed an engineered composite repair solution to mitigate the existing through-wall defects and prevent leaks should additional issues arise.

The solution comprised six layers of SRS carbon fibre cloth combined with a high-temperature resin system, along with heat blankets to complete the post-cure. This allowed the resin to operate safely at temperatures up to 428°F.

The repair was engineered for a 2-year service life.

Results

Being trained to deliver ICR’s best-in-class composite repairs enabled the contractor to execute a quick and seamless project for the client, despite the size of the repair. Safer and faster than traditional welding methods, they are well-equipped to deliver future repairs on the asset should they be required.

To learn more about Technowrap™, or to make an enquiry with our team, please click here.

Scope

IC Integrity successfully restored a corroded crane cab aboard an FPSO in Western Australia that had been experiencing water ingress.

Our engineered composite repair solution delivered a 20-year design life, sealing the leak, preventing further ingress, and providing structural reinforcement to support loads on top of the cab.

Solution

The Technowrap™ repair used our SRS carbon fibre cloth and DRS resin (Deck Rehabilitation System), and was completed seamlessly by our experienced technicians, supported by the client’s onboard trained personnel – all with minimal impact on operations.

Results

A cost-effective and quick project, this Technowrap™ scope was completed with maximum efficiency and minimal disruption for our client.

Interested in using composite repairs in Australia? You can find out more about our services, or contact a member of our team, by clicking here.

Challenges

- Urgent leak seal

- Through-wall defect

Benefits

- Cost-effective and timely repair

- No hot work or shutdown required

Scope

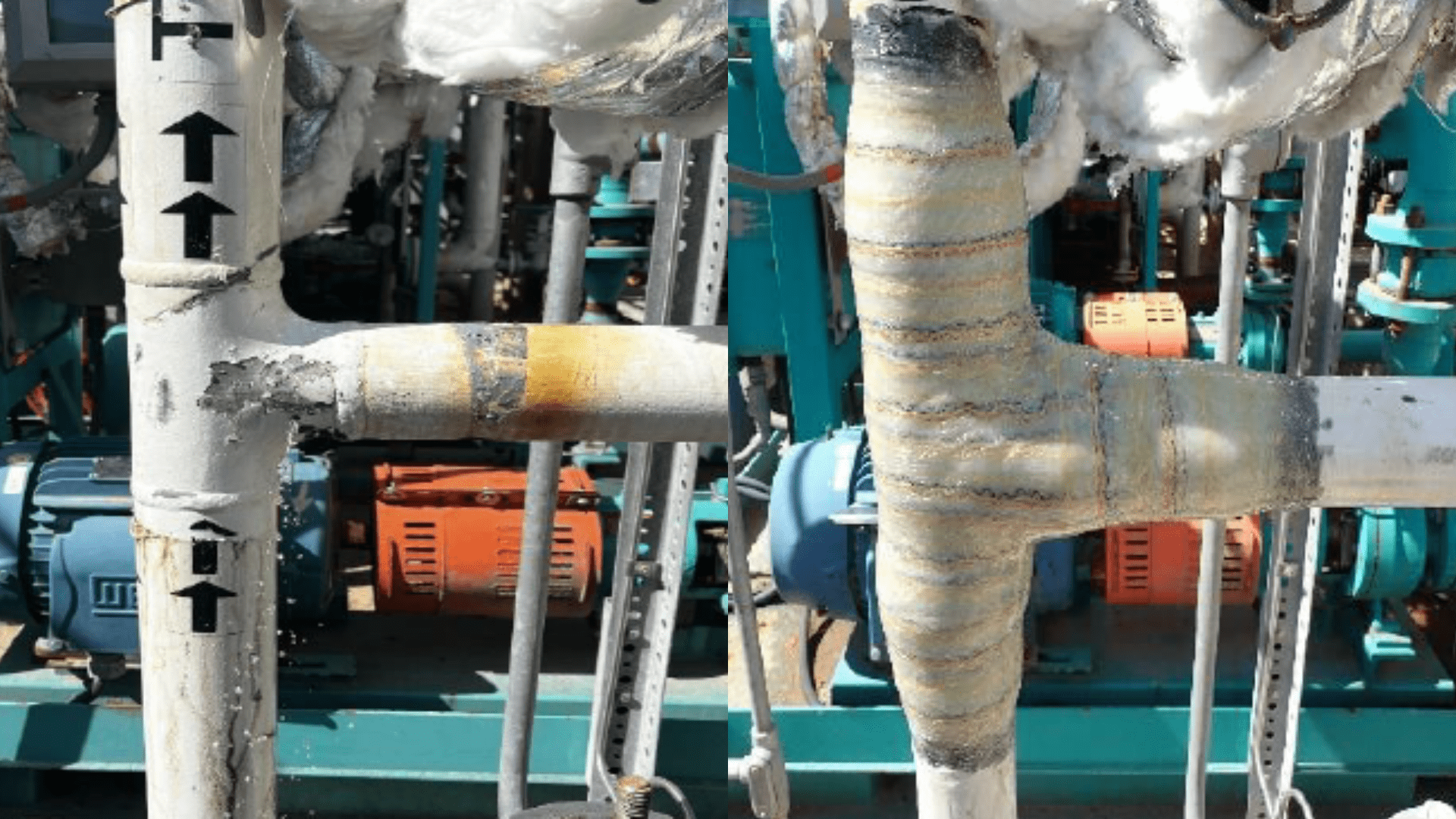

One of the world’s leading energy trading and shipping companies contacted ICR to complete an urgent leak seal, and subsequent engineered composite repair, aboard its liquefied natural gas (LNG) tanker located off the coast of Africa.

The vessel, one of the world’s largest LNG tankers, had suffered a through-wall defect caused by external corrosion on a 24-inch carbon steel tee section in a seawater line. The affected area was identified at a suction point in a deep ballast tank, located on the starboard side towards the aft section of the vessel.

The project scope included performing an urgent leak seal, delivering an engineering design calculation complete with design sketch, and providing the materials and personnel to install the Technowrap™ repair.

Solution

ICR mobilised trained UK technicians and materials to the vessel at the onboarding port. By working closely with the onboard crew and onshore support, ICR maintained effective communication throughout the successful repair process. While the technicians were onboard, ICR also supported the vessel crew by demonstrating the live leak seal procedure in case any initial repairs were required while awaiting an LR-approved repair.

The live leak seal was completed using Technoseal Epoxy Putty. Once the live leak seal was complete, the client mechanically prepped the affected surface area achieving a cleanliness of ST3, and a minimum surface roughness of 40 microns.

ICR’s technician then applied the composite repair which used a combination of Technowrap 2K™, a multi-directional glass cloth, and a high ambient (HA) resin. A successful leak seal test was completed after the first two layers were applied, before the subsequent 10 layers were installed.

Result

The project was successfully completed within five day shifts. ICR was able to quickly mobilise materials and personnel to the vessel and meet the urgent repair needs within the desired timeframe and budget.

Completed while avoiding any hot work or shutdown, this project showcased the advantages of using ICR and Technowrap™ for live leak seal and composite repairs.

Please click here for more on our Technowrap™ composite repairs or to get in touch with our team.

Challenges

- Multiple repairs

- Offshore platform

Benefits

- Quick and cost-effective repair

- No shutdown required

Scope

A global oil and gas operator has utilised ICR’s composite repair technology, Technowrap™, to complete multiple repairs on its Utilities and Quarters (UQ) platform in the North Sea.

During a routine assessment, the operator identified several areas of corrosion on the accommodation roof and approached ICR for a quick, cost-effective, and long-term solution with a 20-year design life. The repair needed to reinforce the remaining carbon steel, which averaged 1mm in thickness, with a design load of 0.005/mm².

The project scope included working with the onboard inspection and FM team to ensure that the Technowrap™ application ran smoothly and was within the design requirements for ISO 24817. Following the inspection, the FM team were instructed to cold bond carbon steel plates to which the Technowrap™ SRS/DRS was then applied to bring the wall thickness to the operational requirements.

Solution

ICR collaborated with Stork, a global provider of integrated operations, maintenance, modification and asset integrity solutions, to deliver a suitable adhesion level through surface preparation as well as the use of various compression aids to allow for an even surface.

When engineering the design for this project, our experts considered the client’s specific requirements while ensuring compliance with industry standards. After design calculations were complete, our team determined an optimal solution compromising Technowrap™ SRS (Structural Rehabilitation System) – a carbon fibre cloth – and DRS (Deck Rehabilitation System), a rubber toughened epoxy resin.

Three layers of this solution, resulting in a repair thickness of 2.70mm, would restore the integrity of the roof areas while ensuring a 20-year design life.

Result

Requiring just one technician and one supervisor to complete the multiple repairs within the desired timeframe, this proved to be a very cost-effective and efficient project for our client.

Pleased with the results, the operator has requested our continued support for additional composite repairs in other areas of the asset.

For more on our Technowrap™ composite repairs or to get in touch with our team, please click here.

Challenges

- Significant wall loss

Benefits

- Collaboration with Ghana-based partner

- Quick and cost-effective repair

- No shutdown required

Scope

ICR has collaborated with its Ghana-based partner, Gecric Asset Integrity Management Limited, to restore the integrity of an air buffer bottle aboard a customer’s floating production storage and offloading (FPSO) vessel.

Located off the coast of Ghana, the customer identified significant wall loss on the asset due to external corrosion. Seeking a quick and effective solution, the customer requested the design and installation of an engineered composite repair solution with a 10-year design life.

Solution

The Technowrap™ composite repair solution was expertly designed for installation on the remaining 1.8mm wall thickness and to meet the required 10-year design life. The wall loss was quickly restored using ICR’s Technowrap™ 2K cloth type and high-temperature (HT) resin.

Surface preparation was completed to a cleanliness level of ST3 and a minimum surface roughness of 54 microns before 15 layers of the Technowrap™ engineered solution were installed, ensuring the air buffer bottle’s integrity was restored and the 10-year design life was achieved.

Extensive quality checks were completed throughout the project to verify the repair’s effectiveness.

Result

By partnering with Gecric Asset Integrity Management, we quickly mobilised Ghana-based technicians and materials to the FPSO before completing the repair within five-day shifts.

The project was safely executed without shutdown, further ensuring the repair was both cost-effective and timely.

Click here to learn more about Technowrap™, or here to get in touch with our team.

Challenges

- Live leak seal repair

Benefits

- Cost-effective

- Quick repair

- No shutdown required

Scope

A full-service terminal and processing facility requested ICR to perform a live leak seal at its multi-modal transfer facility in Galveston, Texas, USA. The repair was required on a 3” carbon steel tee on a wastewater line that had suffered a through-wall defect caused by internal and external corrosion.

Following the live leak seal, ICR was requested to complete an engineered composite repair solution with a design life of 10 years to restore the integrity of the line. The scope included an engineered design calculation, complete with a design sketch, materials, and personnel to execute the repair.

Solution

After ensuring the leak was effectively sealed, the piping was surface prepped for the Technowrap™ application using a bristle blasting method, which ensured a cleanliness level of ST3 and a minimum surface roughness of 40 microns.

Following surface preparation, ICR personnel applied two of the 10 required layers before conducting a successful leak seal test. The remaining eight layers were then installed using a combination of our 2K cloth type and low-temperature (LT) resin.

Result

The leak seal and Technowrap™ repair successfully restored the line’s integrity, while a 10-year design life was met.

As ICR quickly completed both the live leak seal and the Technowrap™ repair, the project remained cost-effective and timely for our customer. This project further demonstrates the effectiveness of Technowrap™ in supporting urgent repairs.

Click here to learn more about our composite repair technology, or reach out to our team here.

Challenges

- 550 meter repair

- Pipeline lifting

- Welded saddle supports

Benefits

- Cost-effective alternative

- Quick installation

- No shutdown

Scope

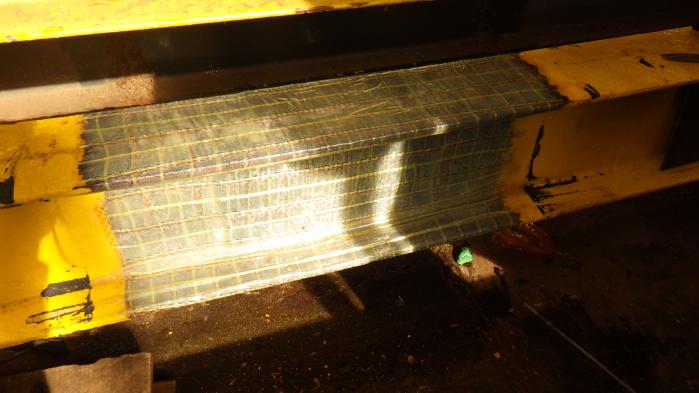

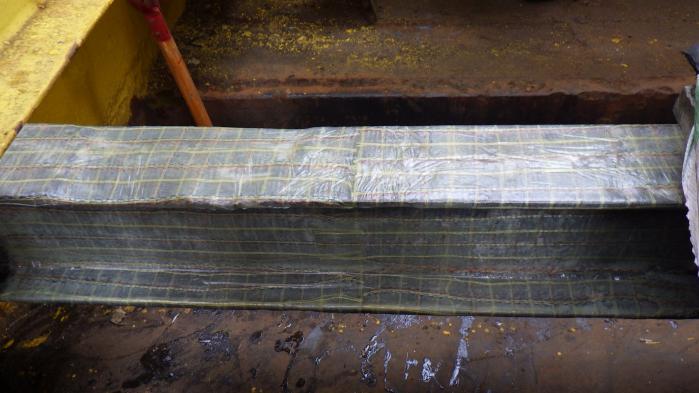

A 32” produced water line had significant internal erosion/corrosion at the 6’oclock position with a minimum remaining wall thickness of 4mm. The length of pipeline requiring repair was approximately 550 meters which contained various saddle supports, some of which were welded. The client required a qualification test of the proposed repair solution, on site, prior to installation of the actual repair.

Solution

The scope of work was to provide an engineered design, with 20 year repair lifetime, trained personnel and Technowrap 2K™ with Technowrap HP PRS™ materials to affect repair. Design pressure of the line was 47Barg, with design temperature of 82DegC.

Result

The installation procedure of the composite repair as demonstrated on the test spool, was approved by the client and produced for site installation. To complement the repair application procedure, a detailed lifting plan of the pipeline over the supports was created to ensure complete encapsulation of the pipeline. Additional requirements of applying the repair on all areas of the pipework included where the pipe work rested on the pipe supports.

For more on our Technowrap™ composite repairs, click here.