Challenges

- Space constraints

- Hydrocarbon lines – no hot work permitted

Benefits

- 100% cold work solution

- Quick and cost-effective solution

- Dedicated engineering support

Scope

A major independent oil and gas company engaged ICR to assist with the decommissioning of three 6” hydrocarbon lines at its onshore gas-processing and reception terminal in North East England, United Kingdom.

With a long-standing relationship with ICR, the customer recognised that ICR’s 100% cold-work technology, Quickflange™, was the optimal solution for this scope providing a far safer and significantly faster installation method than any traditional alternative.

Solution

After reviewing the line conditions, our technical team determined that three 6” Sch40 150# Quickflange™ installations were required. An initial engineering assessment identified potential space constraints that could impact execution, particularly around the use of a standard clamshell cutter for the necessary cold cuts.

A detailed review of site information and updated scope modelling confirmed that sufficient access was available and that a standard clamshell cutter could be used without issue. With accessibility verified, the client was assured that the installations could proceed efficiently using the Quickflange™ solution.

With all technical considerations addressed, ICR mobilised an experienced technician along with the required cutting, installation, and testing equipment to safely and effectively deliver the work on site.

Results

Each installation underwent full QA/QC testing, confirming the integrity and reliability of the lines. The work progressed smoothly across just two shifts, demonstrating both the efficiency of the Quickflange™ solution and the expertise of the onsite team.

The project was completed without the need for any hot work, delivering a safe, cost-effective, and low-risk outcome for the customer. The redundant lines were successfully decommissioned and sealed with blind flanges, ensuring permanent isolation and long-term assurance.

Contact Us

To learn more about this technology, or to make an enquiry with our team, please click here.

Challenges

- No hot work permitted

Benefits

- 100% cold work solution

- Rapid turnaround

- Cost-effective scope

- Seamless installation

Scope

A global energy company engaged ICR to perform a Quickflange™ installation aboard one of its major deepwater oil-and-gas production hubs in the Gulf of Mexico.

With a strong, long-term relationship already in place, the customer knew our 100% cold-work technology was the optimal solution for this scope, particularly as no hot work was permitted. The platform featured a 10” carbon steel vent line that was suffering from corrosion.

Solution

Once the solution was designed, ICR quickly mobilised materials and personnel to the platform. A cold cut and surface preparation were completed on the vent line before installing a 10” S40 carbon steel Quickflange™ connector.

After being pressure-tested to confirm the integrity of the line, a permanent flange-to-pipe connection was established, returning the line to full service.

Results

This was a seamless execution from start to finish, from initial mobilisation to departing the asset in less than two days. Estimated to be 80% faster than welding, this project demonstrated the advantages of our Quickflange™ technology: faster, safer, and more cost-effective.

We now look forward to completing future scopes for this major energy company and continuing to support its asset integrity challenges.

Interested in utilising Quickflange™ in your operations? Please reach out to our team here.

Challenges

- Multiple Quickflange™ connector installations

- 24-hour project window

Benefits

- Completed in desired budget and timeframe with located partner

Scope

An international supplier and operator of offshore floating platforms engaged ICR to restore the integrity of a 10” defected pipe section aboard an FPSO located off the coast of Ghana.

The project required completion within 24 hours and included the installation of two 10” Quickflange™ weldless connectors.

Solution

This successful project highlighted the strength of ICR’s global partner network, as our experts collaborated with Ghana-based Gecric Asset Integrity Management. By leveraging a local partner, we ensured rapid mobilisation of experienced personnel and equipment to meet the tight 24-hour deadline.

Our project team, consisting of two experienced Quickflange™ technicians, executed the cold cutting and removal of the defected pipe using a clam shell cutter. Precise rigging was used to safely suspend and extract the damaged section.

After removal, both pipe ends were surface prepped ahead of the installation of a new 10” spool and two 10” Sch 40 Quickflange™ connectors. Once safely installed using a bespoke Quickflange™ activation tool, flange joint testers were used to confirm a successful seal with no leaks or defects.

Results

Despite the challenging turnaround, our partnership with Gecric proved highly effective, allowing all works to be completed within 24 hours. The client was left with a fully restored, leak-free pipeline.

This project demonstrated the advantages of working with ICR and our global partner network, as well as the efficiency of our Quickflange™ technology, which is a proven alternative to traditional welding methods – particularly where time constraints are critical.

Enquire With Our Team

To reach out to our dedicated Quickflange™ team, just fill out this quick form, and a member of our division will be in touch as soon as possible.

Challenges

- Multiple Quickflange™ connector installations

Benefits

- Delivered with local partner

- No hot work

- Delivered on time and within budget

Scope

Our client, a Malaysian multinational oil and gas company, required multiple Quickflange™ installations to support pipework modifications on its onshore asset.

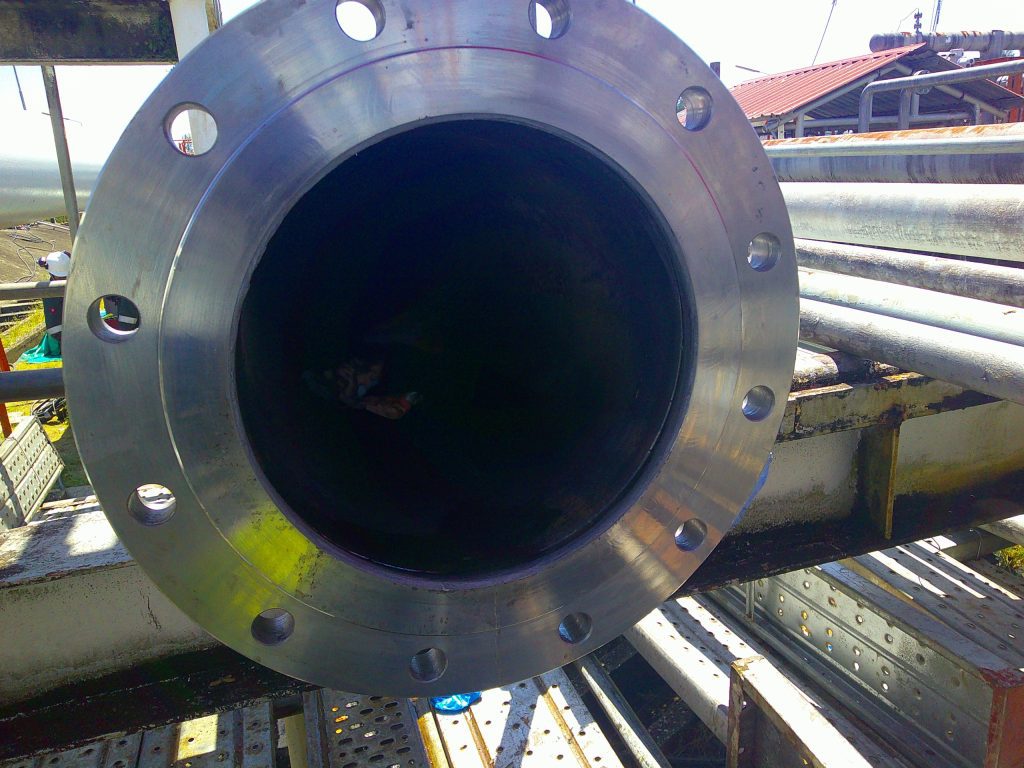

Quickflange™, ICR’s weldless flange-to-pipe technology, was identified as the optimal solution since the client aimed to avoid hot work and welding. The 12” carbon steel pipeline in question was processing hydrocarbon liquid oil.

Solution

ICR collaborated with our Malaysian partner, Preveld, to execute the project. By leveraging Preveld’s local resources, materials, and personnel, the team was able to mobilise quickly and begin the installations.

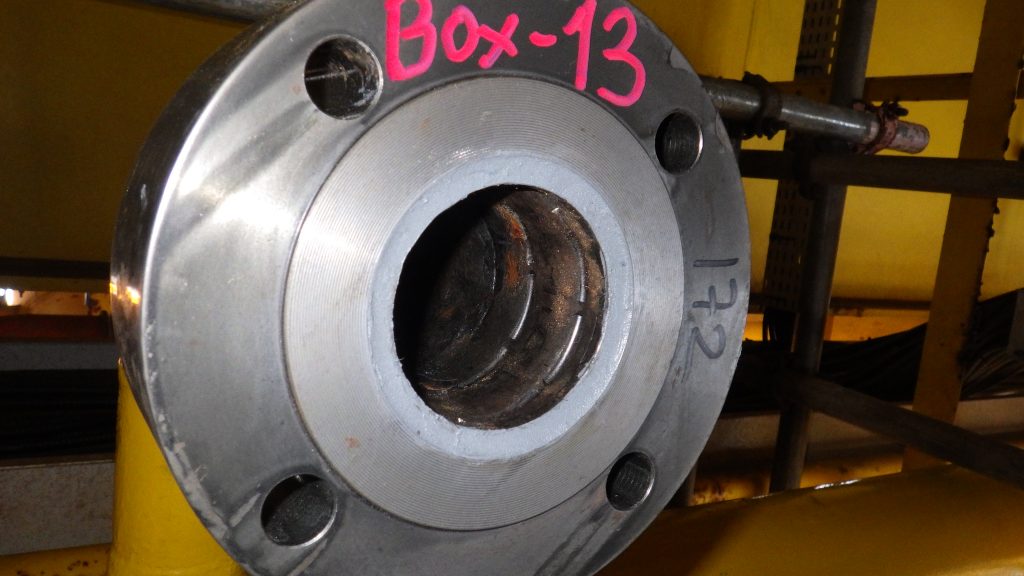

Two Quickflange™ connectors were required on the 12” pipeline to complete the client’s planned modifications. The work began with cold cutting the line, after which the connectors (12” S30 CL 150 RF WN A105N) were installed using the Quickflange™ activation tool. The installations were then pressure-tested to confirm integrity.

Results

The partnership with Preveld delivered a cost-effective and efficient outcome for the client.

By using Quickflange™, hot work was completely avoided. With the client highly satisfied with the results, ICR and Preveld are now exploring further opportunities to support this Malaysian operator.

Enquire Today

Are you interested in utilising Quickflange™ in your operations? Please fill out the form on this page, and our team will be in touch as soon as possible.

Challenges

- Hot work restrictions

- Multiple installations

- Hydrocarbon line media

- Space constraints

Benefits

- No hot work

- Increased safety

- Cost-effective solution

- Quick installations

- Cold work technology

Scope

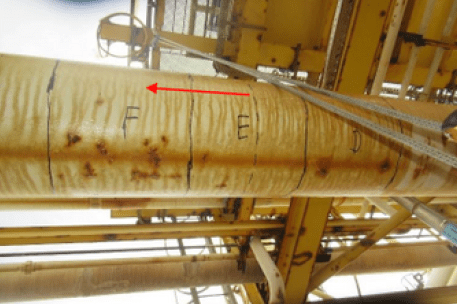

A multinational energy company was approached by our Thailand-based partner, Pipeline and Piling Services Co (PAPS), to resolve the integrity of an open drain utility line at its offshore central processing plant. Located in the Gulf of Thailand, PAPS identified that ICR’s weldless technology, Quickflange™, would be an optimal solution for repairing the 3” galvanised pipeline which was made from seamless carbon steel.

After assessing the pipeline, ICR’s experts determined that multiple Quickflange™ installations were required. To ensure the project was cost-effective and timely, PAPS technicians, who are trained and qualified to complete Quickflange™ installations in the region, were mobilised at short notice to complete the scope.

Solution

Once the technical review was complete and the solution was designed, the necessary tools, flanges, and personnel were quickly mobilised to the site. After isolating the lines, straight cuts to the pipe were prepared in each of the repair zones to allow the project technicians to progress through the various installations. All repairs utilised a 3” Sch160 Carbon Steel 150# Quickflange™ connector, each of which were hydrostatically tested after each installation to verify the integrity of the repair.

Results

Despite the considerable number of installations required and the limited space in some repair zones, the project was completed safely with maximum efficiency. From initial reviews to offshore work and final demobilisation, each stage of the project was completed on time and within budget.

Our partner completed 17 Quickflange™ installations in just 4 days. By utilising Quickflange™ technology over traditional welding techniques, our client cut the project timeline by an estimated 30 days. The outstanding results have led to the identification of additional scopes with the operator, securing further collaboration with ICR in 2025.

To discover more about our Quickflange™ technology, or to submit an enquiry to our team, please click here.

Challenges

- Remote location

- Extreme environment

- High-grade carbon steel

Benefits

- No hot work

- Minimal downtime

- Increased safety

Scope

The primary objective of this project involved the removal and replacement of a deteriorated section of API-5L Grade X42 line pipe, which had suffered significant corrosion over time. This required the installation of a prefabricated spool measuring 50 metres in length. The worksite’s remote desert location added unique logistical challenges, including limited accessibility, extreme environmental conditions, and the need for precise coordination to ensure seamless delivery and installation of the replacement spool. Despite these constraints, the project was designed to ensure minimal disruption to operations while adhering to strict industry standards and safety protocols.

Solution

Quickflange™ was selected as the preferred cold work repair solution. Trained personnel from our local partner were mobilised to the site to carry out the activations. After isolating the pipeline, a cold cut was performed on the corroded pipe section, and the pipe ends were prepared to accommodate the 6″ Sch40 Class 600 API-5L Grade X42 Quickflange™ connectors. Upon completion of the installations, each connector underwent hydrostatic testing in accordance with the client’s specifications.

Result

The successful installations were completed within a single shift. From pipe cutting to final activation, both installations were finished in a combined total of two hours. By employing a cold work method, the need for hot work was entirely eliminated, significantly reducing risks and ensuring strict compliance with safety protocols. This approach not only minimised downtime but also demonstrated the effectiveness of Quickflange™ in delivering fast, reliable pipeline repairs.

For more on our Quickflange™ technology, click here.

Client: North Sea operator

Location: United Kingdom – North Sea

Challenges

- Hydrocarbon flare line

- Hot work restrictions

- Installation at height

Benefits

- No hot work

- Increased safety

- Cost-effective solution

- Large bore connectors

Scope

A North Sea operator identified a critical issue with its high-pressure flare collection header. The 10″ blowdown pipework was at risk of low-temperature embrittlement and required urgent modification. The repair posed several challenges, including the hydrocarbon nature of the line, its five-metre height, and the constrained shutdown window. To ensure a safe and efficient resolution, the operator collaborated with Katoni Engineering, who designed and engineered the pipework replacement using Quickflange™ technology.

Solution

The scope included the installation of a 10” Sch20 150# Carbon Steel Quickflange™. Before installation, temperature and impact testing requirements were carefully reviewed, with Quickflange™ meeting all compliance standards. The existing pipework was removed using clamshell cutting equipment, ensuring a precise, straight cut for the Quickflange™ installation. Following installation, a hydrostatic strength test was successfully performed using a flange joint tester, verifying proper installation with no leak paths.

Result

The Quickflange™ installation was completed in just one shift, allowing the team to efficiently progress through the remaining shutdown tasks. The elimination of hot work was particularly significant given the hazardous environment, enhancing both safety and operational efficiency. Compared to conventional welding methods, Quickflange™ offered a more economical solution while minimising downtime. Additionally, the client benefited from the availability of large-bore Quickflange™ connectors, perfectly suited for the specific work scope requirements.

For more on our Quickflange™ technology, click here.

Client Challenge

Our client, an energy operator in Azerbaijan, faced the challenge of tying in new 6” & 8” carbon steel spools on the asset’s drill floor low-pressure mud lines. Traditional welding methods posed risks due to the presence of hydrocarbons, necessitating a cold-work solution to avoid hot work and mitigate associated hazards. Our client urgently required a reliable method to conduct the tie-ins without compromising safety, operational downtime, or incurring additional costs.

What We Did

In response to our client’s challenge, our weldless connector technology, Quickflange, was the preferred cold-work solution to facilitate the pipeline tie-ins. Quickflange’s innovative design eliminates the need for hot work, habitats, and associated safety risks, ensuring a safe and efficient repair process.

Collaborating with our partner, Khazar Engineering in Azerbaijan, our team mobilised equipment and trained technicians to execute the repair swiftly and effectively. Khazar’s trained technicians undertook line preparation, cold cutting of the pipe, and the installation of Quickflange connectors. Additionally, they provided essential support for the installation of the new spool tie-in sections, ensuring seamless integration with the existing pipeline infrastructure.

Results:

The implementation of Quickflange enabled a rapid turnaround for the client, addressing the repair needs on short notice without compromising operational efficiency. The elimination of hot work not only minimized downtime but also resulted in substantial cost savings compared to traditional welding methods.

With Quickflange, our client achieved a permanent repair solution that meets safety standards while optimizing operational resources and costs. The successful collaboration between ICR, Khazar Engineering, and the client highlights the effectiveness that Quickflange generates when addressing complex repair challenges in offshore environments.

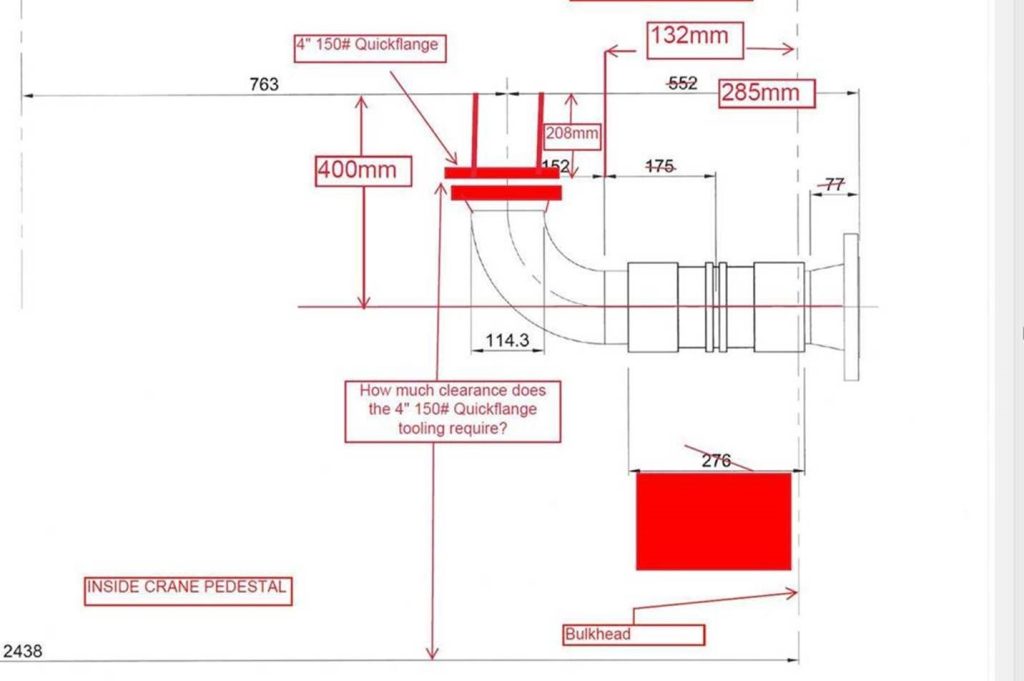

Client challenge

A major North Sea operator encountered a significant challenge when dealing with a leaking 4” Sch80 carbon steel nozzle crucial for a diesel tank’s operation. Complicating matters, the application of hot work methods was obstructed by time constraints and extreme space restrictions in the confined void where the nozzle was located, rendering conventional welding impractical.

What we did

This project presented several challenges, including the proximity of an i-beam, tight clearances, limited rigging options, and confined spaces. Within a 48-hour timeframe from the initial request, we successfully mobilised all necessary equipment, minimising downtime for our client. Post-installation, a thorough testing of the Quickflange™ joint ensured its integrity, conforming to both industry and client standards.

Results

The implementation of our weldless connector technology, Quickflange™, resulted favorable outcomes for our client. The repair process eliminated the need for hot work, addressing safety concerns and aligning with the client’s operational restrictions. Our tailored approach navigated extreme space restrictions, surpassing challenges unmatched by competitors.

The swift mobilisation of equipment within an impressive 48-hour timeframe significantly reduced downtime and operational disruptions. This rapid resolution showcased the effectiveness of Quickflange™ technology and demonstrated our capacity to deliver innovative solutions under challenging circumstances.

The impact included enhanced safety measures, increased operational efficiency, and substantial cost reductions associated with the repair process. This case study underscores our commitment to providing comprehensive solutions that prioritise safety, efficiency, and cost-effectiveness for our clients.

Client: Local EPC

Asset: Offshore platform

Result: Replacement of critical hydrocarbon, utility gas and air lines

Client Challenge

Our client faced a critical challenge in designing in the replacement of failing hydrocarbon, utility gas and air lines of various sizes. They also required the supply of a 3” Quickflange to enable the blinding of a line that would no longer be in use. The replacement of these essential lines was time-sensitive, as it required shutdowns to ensure safety and continued operations.

What we did

Our approach involved several key steps to address the client’s challenge of replacing the failing lines across 1×2”, 1×3” utility lines, 3x 1.5” lines, 1x 8” and 1×10” hydrocarbon sizes effectively:

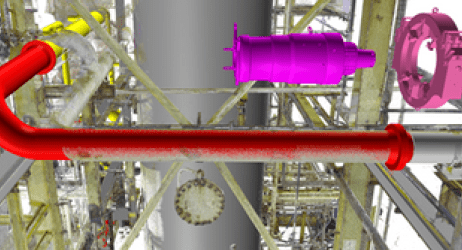

3D modelling: We provided 3D modelling to help with the planning and that the cutting, Quickflange™ tooling and test equipment could be effectively utilised within the available space.

Manufacturing of Quickflanges: We manufactured galvanised 2” and 3” Quickflanges for the initial part of the project. For the hydrocarbon lines, we custom-forged Quickflanges and painted them according to operator specifications.

Match boring: All lines required match boring before installation, which we factored in and completed as part of the planning and installation process.

Collaboration: We worked closely with our client to transform plans into quotes, establish timelines, and determine the necessary workforce for the project.

Contingency planning: Recognising the critical nature of the project, we provided contingency tooling and kept additional tools ready in our warehouse for immediate dispatch if required.

Technician support: We supplied two highly trained technicians with expertise in Quickflange™ installation and match boring from our machining division. This allowed for flexible day and night shifts as necessary to meet the time-critical installation requirements.

Minimising downtime: Throughout the project, we took every aspect into consideration to minimise the shutdown period and expedite the resumption of production. Quickflange™ technology was instrumental in achieving a significant reduction in time compared to traditional welding. All cutting, match boring, and installations across the platform were successfully completed in just three days.

Results

Our collaborative approach, advanced Quickflange™ technology, and comprehensive planning resulted in a successful outcome.

The replacement of critical hydrocarbon, utility gas and air lines was completed efficiently, reducing downtime. The project was accomplished in just three days; a 50% reduction in time compared to traditional welding methods. The client achieved their goal of ensuring the safety and reliability of their hydrocarbon, gas and air lines, supporting uninterrupted operations.