| Date | Client | Location |

|---|---|---|

| August 2021 | Major Operator | Southern North Sea |

Scope

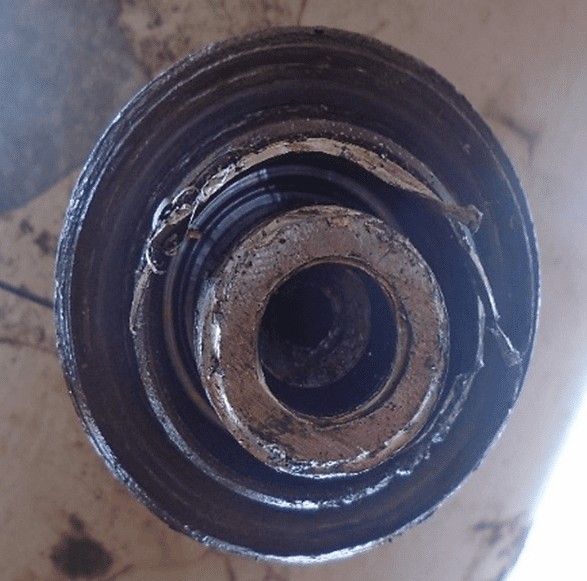

We were requested to service and refurbish a number of access fittings during the platform shutdown. These access fittings were in poor condition and, for some, the historical service history was not known. When servicing the import flowline location the internal carrier plug was found to seized half way in the fitting and attempts to remove (by the previous service company) had resulted in significant damage to the plug (Pic 1). The carrier plug would not have been holding pressure and the only historical isolation on this line was provided by the heavy duty cover. The line could not restart until the issue was rectified.

Solution

ICR mobilised an on-site machining technician and specialist drilling equipment. The drilling equipment is designed specifically to remove seized carrier plugs from access fittings. It uses a hollow cutter which allows the carrier plug threads to be removed without damaging the internal threads of the access fitting (Pic 2). This allows the remaining plug section to be removed before the internal threads are tapped and a new carrier plug installed.

Results

- ICR were able to remove the seized carrier plug safely without causing any further damage to the access fitting

- A new carrier plug was fully installed (Pic 3) along with a new heavy duty cover

- A leak test was then conducted to confirm a seal and that the integrity of the line had been restored (Pic 4)