Challenges

- Multiple Quickflange™ connector installations

Benefits

- Delivered with local partner

- No hot work

- Delivered on time and within budget

Scope

Our client, a Malaysian multinational oil and gas company, required multiple Quickflange™ installations to support pipework modifications on its onshore asset.

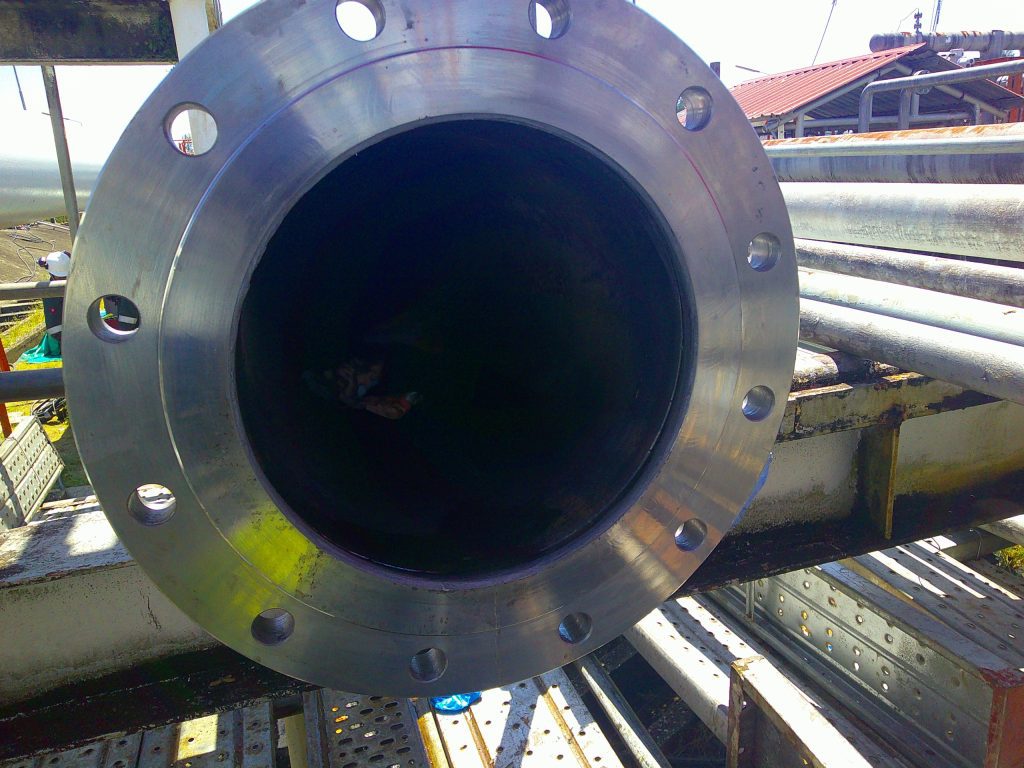

Quickflange™, ICR’s weldless flange-to-pipe technology, was identified as the optimal solution since the client aimed to avoid hot work and welding. The 12” carbon steel pipeline in question was processing hydrocarbon liquid oil.

Solution

ICR collaborated with our Malaysian partner, Preveld, to execute the project. By leveraging Preveld’s local resources, materials, and personnel, the team was able to mobilise quickly and begin the installations.

Two Quickflange™ connectors were required on the 12” pipeline to complete the client’s planned modifications. The work began with cold cutting the line, after which the connectors (12” S30 CL 150 RF WN A105N) were installed using the Quickflange™ activation tool. The installations were then pressure-tested to confirm integrity.

Results

The partnership with Preveld delivered a cost-effective and efficient outcome for the client.

By using Quickflange™, hot work was completely avoided. With the client highly satisfied with the results, ICR and Preveld are now exploring further opportunities to support this Malaysian operator.

Enquire Today

Are you interested in utilising Quickflange™ in your operations? Please fill out the form on this page, and our team will be in touch as soon as possible.