Challenges

- Multiple significant defects

Benefits

- Cost-effective

- Quick installation

- No hot work

- Completely engineered repairs

Scope

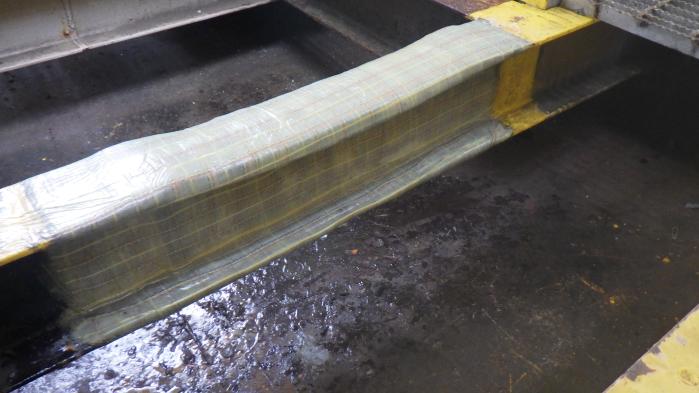

A leading multinational energy and petrochemical company engaged ICR to restore several corroded I-beams using Technowrap™ engineered composite repairs.

Located offshore Malaysia, the asset featured six carbon steel I-beams suffering from corrosion, with an average remaining steel thickness ranging from 0.1 mm to 1 mm.

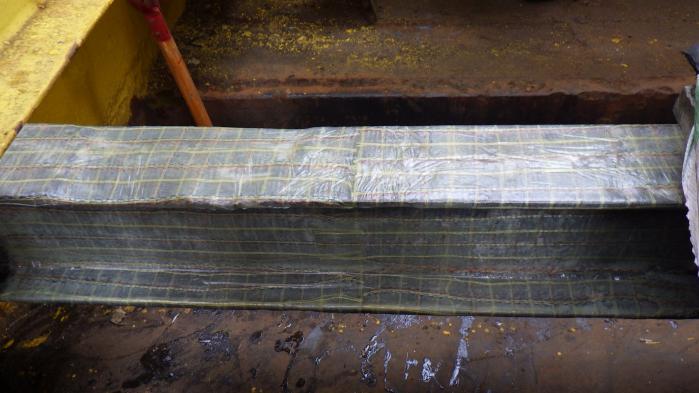

The customer requested that ICR restore the load bearing capacity of the I-beams with engineered repairs designed for a 20-year service life.

Solution

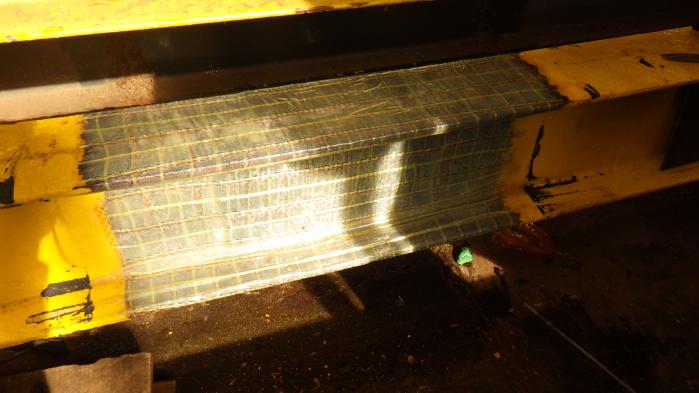

After analysing the corroded I-beams, ICR’s technical team determined that a Technowrap™ solution comprising two to four layers of 2K glass fibre cloth with High Ambient (HA) resin would effectively repair each defect and ensure a 20-year design life.

In conjunction with a local partner, highly experienced technicians and materials were mobilised to the asset to install the engineered repairs which were completed with minimal disruption, ensuring no production downtime.

Final QA/QC inspections were completed on each repair, verifying the quality of every Technowrap™ installation.

Results

This project highlighted the speed, versatility, and reliability of Technowrap™. Despite significant defect sizes, all repairs were successfully restored to achieve a 20-year design life.

As a safer and more cost-effective alternative to steel replacement, we look forward to helping more customers across Asia adopt this technology in their operations.

Contact Us

If you have a question about this case study, or would like to enquire about using Technowrap™ in Malaysia, then please contact our International Business Development Manager, Iain Masson (iain.masson@icr-world.com).