Scope

To supply an electric drive Pour Point Depressant injection package. Injection Rate: 0-1800 litres per hour Duty Process Pressure: 13.8 barg Fluid Viscosity: Up to 600 cP Ambient Temperature: -15 to +30 °C Skid ATEX Classification: Zone 2 IIA T3 Power Requirement: 440V 3ph 50hz Chemical reservoir: Tanker (by others)

Required Injection Rate: 0-1800 litres per hour

Duty Process Pressure: 13.8 barg

Fluid Viscosity: Up to 600 cP

Ambient Temperature: -15°C to 30°C

Skid ATEX Classification: Zone 2 IIA T3

Power Requirement: 440V 3ph 50hz

Chemical reservoir: Tanker (by others)

Solution

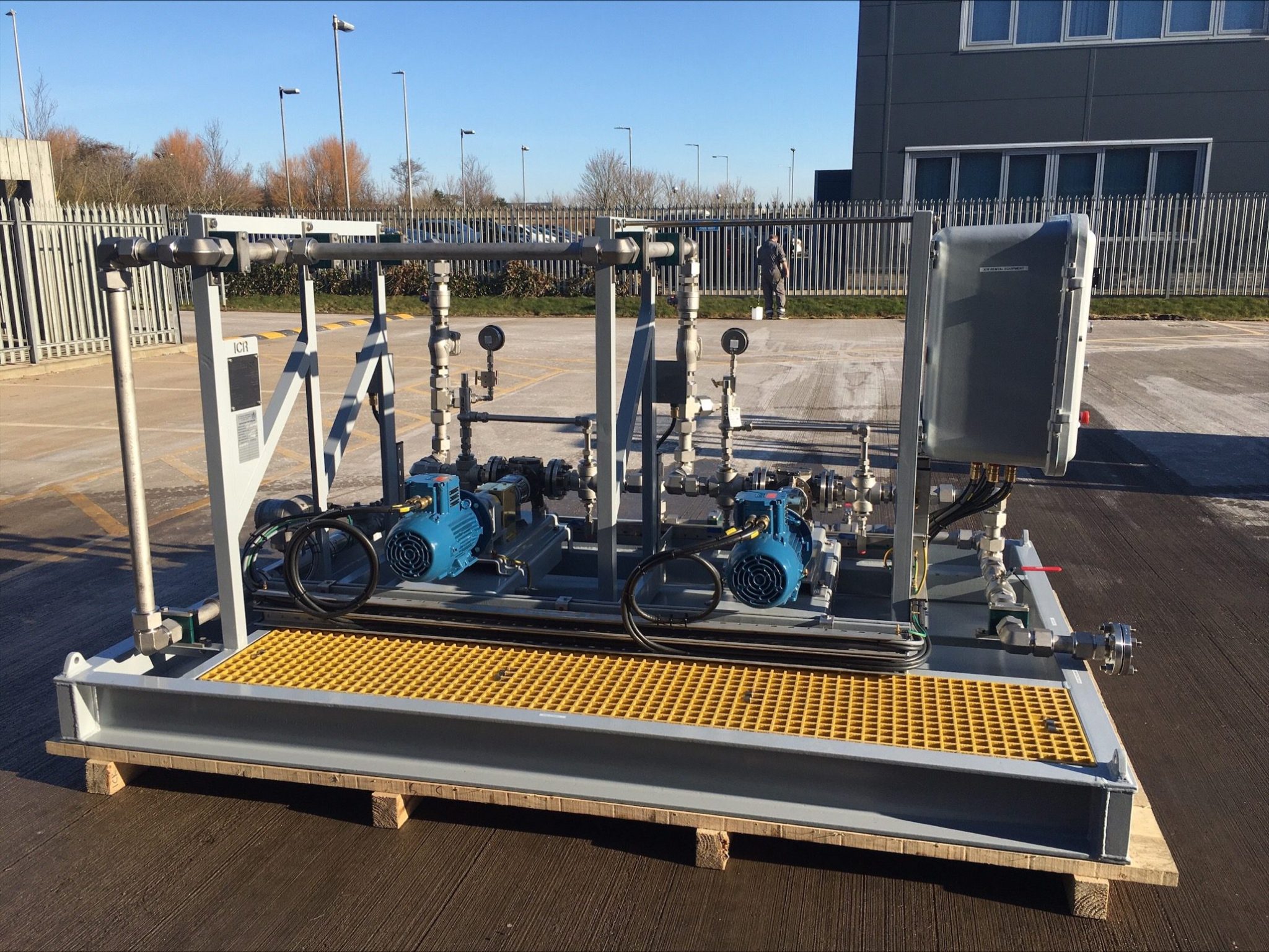

- ICR proposed SPX Flow Internal Gear Pumps in a duty/standby arrangement c/w variable speed electric motors

- Motor speed was locally controlled by a skid-mounted Ex d control panel

- Coriolis Flowmeter power supplied via the control panel

- On-skid equipment earthing provided along with On-skid cable support system

- Package was installed on a painted carbon-steel base frame c/w integral sloping drop tray with drain valve, certified lifting points, sling set and spreader lift beam

- Tubing, fittings, valves and components supplied in 316 stainless steel

- Discharge manifold fitted with dissimilar check valves for increased reliability

Results & Benefits

- Pumps capable of pumping viscous fluids at the required flowrate

- Bespoke control system configured to accept incoming power from client distribution board Overpressure safety built into design with discharge pressure relief valves

- Stable discharge flow and pressure through use of pulsation dampeners

- Real time flow rates and cumulative flow displayed locally on Coriolis flowmeter