Client: Major operator

Location: Freeport, Texas – USA

Scope

During a routine inspection of pipe systems, a large operator based in Freeport, Texas, identified a localised area of external corrosion under tmin on a six-inch carbon steel pipeline in butane service.

The operator contacted ICR looking for a long-term, time-sensitive solution to restore the integrity of this straight pipe without shutting down operations. At the customer’s request, the engineered repair solution required a design life of 10 years. The scope of work included engineering design calculations, a design sketch, and materials.

Solution

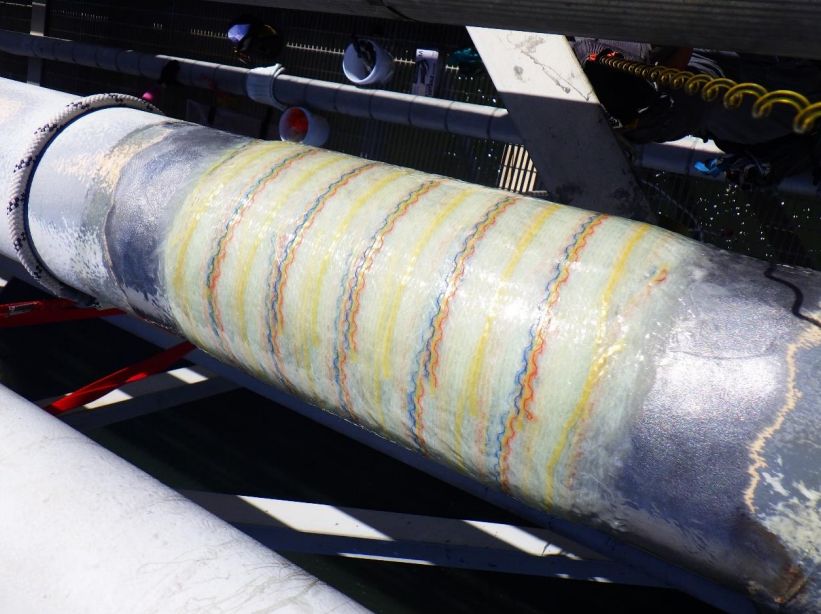

ICR collaborated with its rope access installation partner, Acuren, to surface prep the repair area using a bristle blasting method to achieve a cleanliness standard of ST-3, with a minimum surface roughness of 65 microns/2.5 mils.

Considering the condition of the asset and its environment, ICR design engineers calculated the required repair compliance with ISO 24817 using Technowrap™ High Ambient (HA) system and 2K cloth to achieve the required 10-year design life requested by the customer.

Results

The piping was restored and corrosion mitigated thanks to the experience of the Acuren rope access team, and the fast-acting performance of Technowrap™ HA and Technowrap 2K™ which required 24 hours to cure.

Completed with minimal disruption and without shutting down operations, this project illustrated the cost and time advantages of utilising ICR’s composite repair technology over standard replacement methods. Tested and qualified to ISO 24817 and ASME PCC-2 Article 401 standards, and supported by a 30-year track record across multiple sectors, Technowrap™ promises a cost-effective, reliable, and long-term solution for repairs.

For more information on this solution, click here.