Proven subsea composite repairs, Technowrap™ restores pipeline integrity with 20-year performance

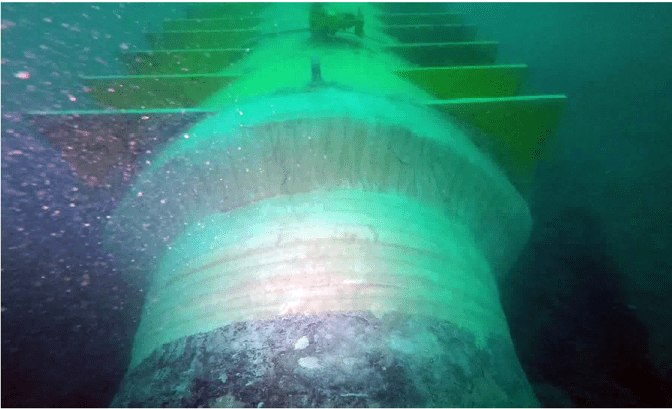

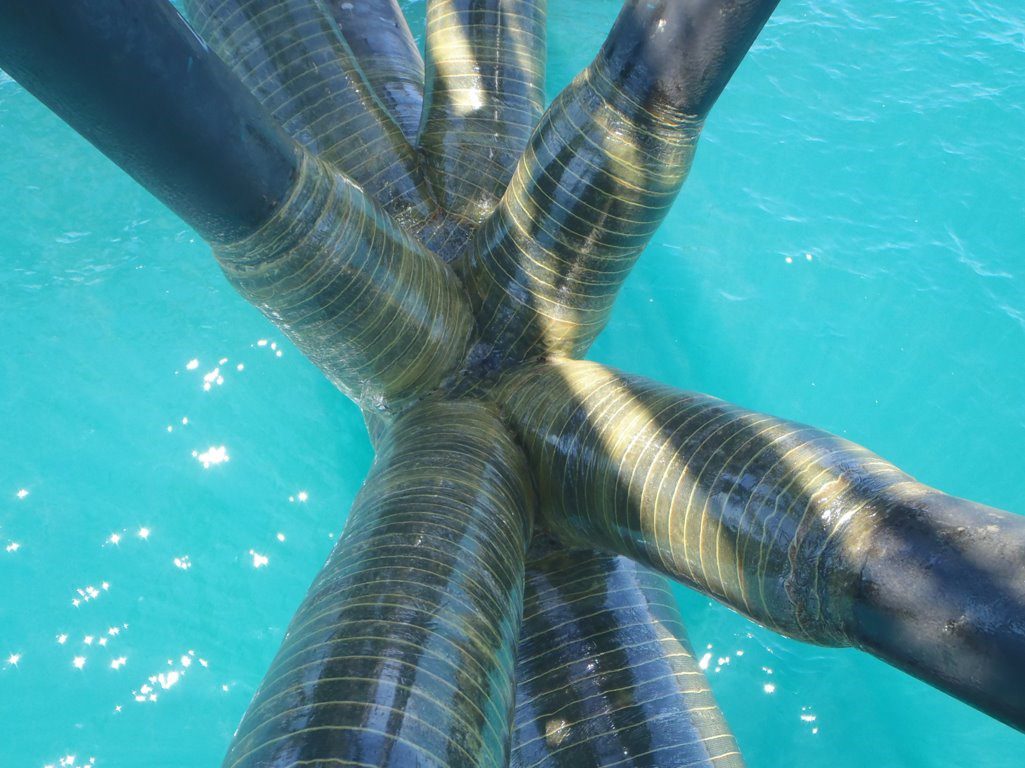

ICR’s Technowrap™ composite repair solution is a specialised wet lay-up system designed to restore integrity to pipelines or piping components operating in wet or humid environments, including subsea.

Our track record of subsea composite repairs span across the globe, including Middle East, Africa, USA, Europe, and beyond.

Reliable and versatile composite repairs

Qualified for repairing both thin-wall and through-wall defects, Technowrap™ solutions can be customised to address specific piping conditions and defect types. Dents and mechanical damage can also be addressed with additional engineering considerations.

Minimising costs, maximising operational safety and production uptime

Technowrap™ composite repairs can be applied by saturation divers with ease, offering a cost-effective alternative to pipeline replacement, clamps, and welded solutions, ensuring operational safety and maximising production uptime.

How does it work?

Technowrap™ solutions combine carbon or glass reinforcement cloths with a hydrophobic epoxy resin that cures underwater and displaces moisture at the bondline, ensuring strong adhesion in wet environments.

Pressure-retaining capabilities depend on defect type, size, pipeline diameter, and any additional load requirements. The repair design is calculated per ISO 24817 or ASME PCC-2 standards, accounting for material properties such as energy release rate, tensile modulus, and thermal expansion coefficient.

Before repair begins, a detailed design calculation is provided to the client. Upon completion, a comprehensive quality control close-out document ensures full traceability and confidence in the repair.

Features, advantages, and benefits

Pressure Limit: Pressure tolerance is dependent on design inputs, including design life, defect type, pipe diameter, and remaining steel thickness. For through-wall defects, where the composite must provide containment, the pressure limitation is typically 20 bar (290 psi). In contrast, for thin-wall defects, where load sharing between the steel and composite is possible, the pressure tolerance can exceed 250 bar (3,625 psi), depending on factors such as pipe diameter, remaining steel thickness, and the specific composite repair system used.

Temperature Tolerance: Suitable for service temperatures up to 66°C/151°F (thin-wall defects) and 56°C/133°F (through-wall defects), covering a wide range of operating environments.

Long-term Reliability: Tested to provide a design life of up to 20 years.

Features, advantages, and benefits

Versatile Defect Repair: Qualified for repairing both thin-wall and through-wall defects, dents and mechanical damage.

Material Options: A choice of carbon fibre (for higher tensile modulus) and glass fibre (for superior adhesion) based on repair requirements.

Standards Compliance: Fully adheres to ISO 24817 and ASME PCC-2 standards that govern the use of engineered composite repairs for pressure equipment ensure a tested, qualified repair solution is provided.

Specialist Application: Installed by ICR certified saturation divers trained through our mandatory training course which can be tailored to represent repair conditions, ensuring consistent, high-quality repairs.

Application Supervision: ICR provides Technowrap™ Repair Supervisors to complete quality control checks ensuring successful work scope execution.

Send us your enquiry

Please complete the form below, and a member of our team will be in touch as soon as possible.