Challenges

- Serious nozzle blockages in chemical injection package

Benefits

- Optimal, cost-effective equipment identified and installed within timeframe

Scope

After installing a fully automated chemical storage and injection system on a North Sea unmanned platform, CIU was asked to help resolve serious nozzle blockages affecting a separate chemical injection package. These blockages caused loss of critical injection, and because the platform is unmanned, offshore trials or remedial work were costly and impractical.

Using CIU’s unique ability to replicate offshore conditions in a controlled workshop, we conducted tests to evaluate various atomizer nozzles under representative parameters, including injection pressure, flowrate, temperatures, and spray patterns. CIU developed the detailed test procedure and rig design, enabling comprehensive data collection and identification of the appropriate equipment, prior to offshore installation.

Solution

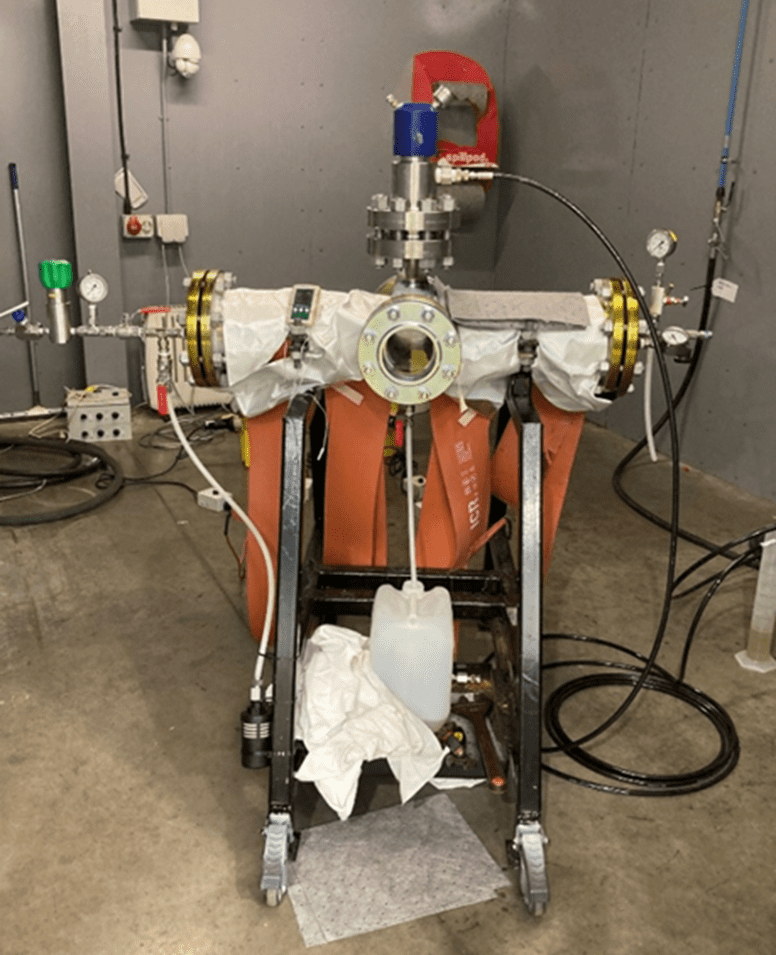

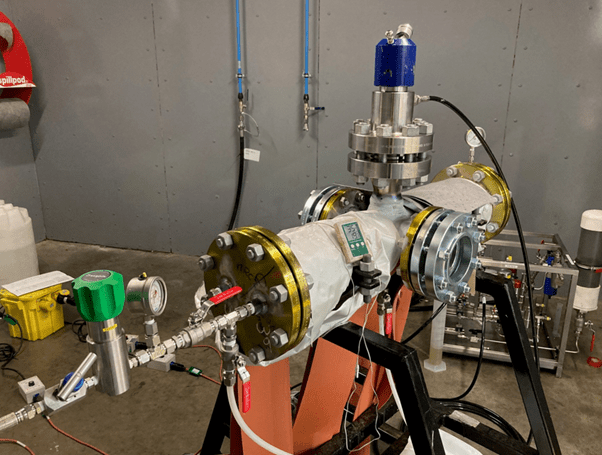

CIU designed and built a bespoke test rig for onshore function testing of injection quills and atomiser nozzles intended for Scale and Corrosion Inhibitor injection on the platform. To account for chemical viscosity changes caused by seasonal temperature variations offshore, tests were conducted at different ambient and chemical temperatures. The following set-up was used to execute the injectivity testing:

- Bespoke 6” test spool c/w Kenco Engineering sight glasses and RTJ flanged injection port.

- Dual pump skid for chemical injection.

- Test chemicals were stored in refrigerator to achieve various fluid temperatures.

- A nitrogen supply was used to pressure the spool. Test spool pressure was adjusted to suit individual test cases, matching onsite process conditions.

- Thermostatic heat blankets were fitted to test spool to adjust and maintain required test temperatures.

- Insulation was installed over heat blankets.

- Waste fluid container was connected to test set-up.

Results

Testing confirmed that several nozzle types and sizes were unsuitable for the designated chemicals and operating parameters, with blockages and poor spray dispersal observed –

issues that would be impossible to identify in a live system.

This allowed CIU to eliminate ineffective configurations before installation, avoiding costly offshore remedial work. Following testing, CIU produced a comprehensive Test and System Optimisation Report, enabling the customer to select the optimal equipment for their operations, while ensuring reliable long-term chemical injection performance.

Interested in learning more about our corrosion monitoring capabilities? Please click here.