Ensuring Integrity and Extending the Life of Composite Repairs

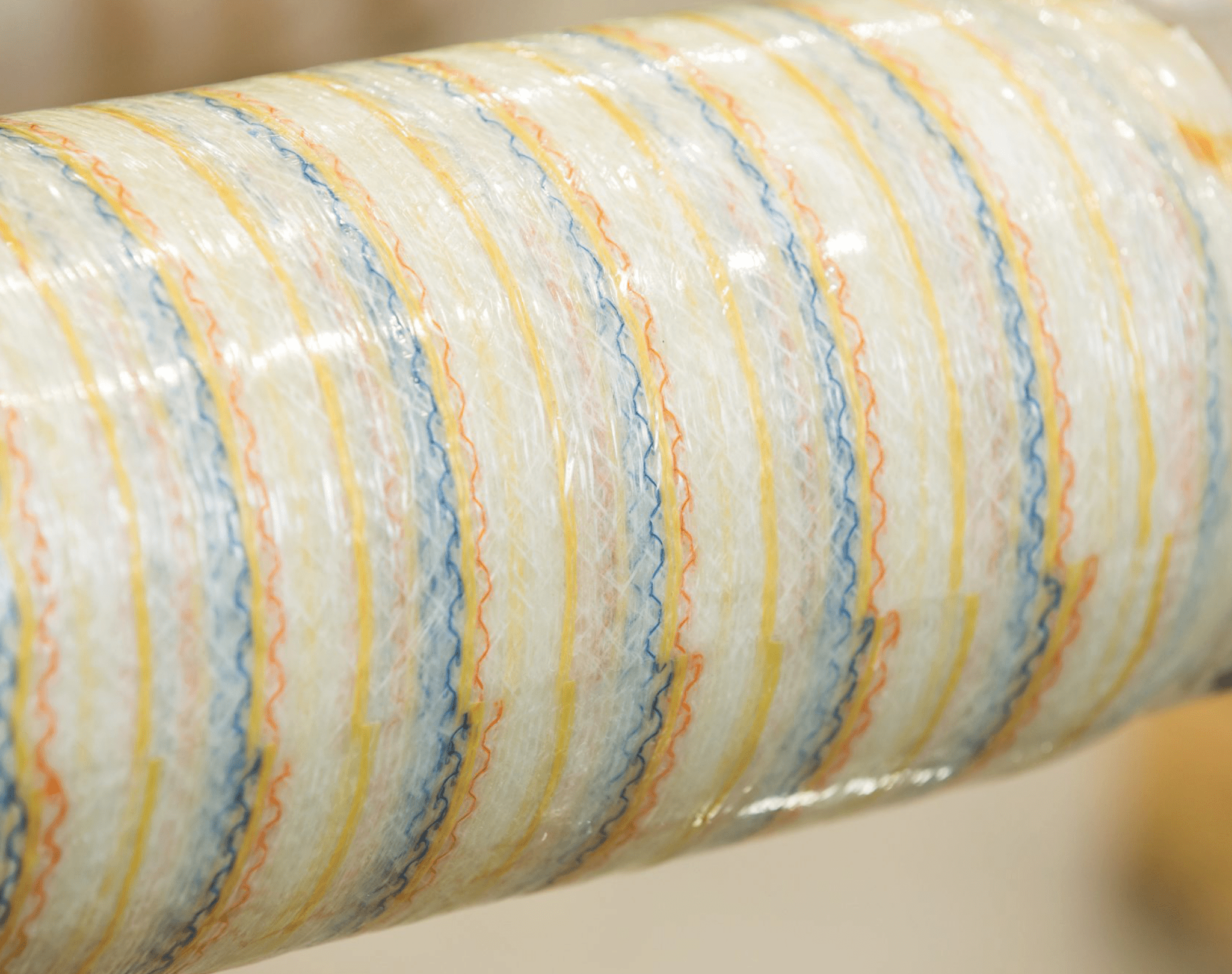

INSONO™ is ICR’s innovative non-destructive inspection system, specifically developed for use with Technowrap™ Engineered Composite Repairs. It utilises acoustic inspection methods; including pitch and catch, resonance, and mechanical impedance analysis to identify delaminations within the laminate and, most critically, disbonds along the bond line.

INSONO™ addresses two key challenges in the composite repair lifecycle:

(1) Validation of repairs throughout their design life

(2) Verification for design life extension beyond the original design life

Its compact, handheld design allows for easy deployment across all typical Technowrap™ repair application geometries, including difficult-to-access areas. The inspection probes are custom-designed to be effective in the specific application zones of composite repairs.

Advantages & Benefits

- Technowrap™-Specific Capability: INSONO™ is tailored specifically for the inspection of Technowrap™ composite repairs.

-

Portability and Accessibility: The handheld unit and interchangeable probes can be used across all system configurations and complex geometries.

-

Compact and Mobile: The full system fits into a small peli case for convenient mobilisation.

-

Trained Personnel: Inspection engineers are uniquely qualified in both composite repair application and acoustic inspection techniques.

-

In-Service Verification: Builds upon existing quality assurance processes by confirming that installed Technowrap™ repairs remain fit for purpose, offering clients added confidence.

-

Sustainability: Enables life extension of existing composite repairs, reducing the need for carbon-intensive steel replacements.

-

Ongoing Condition Monitoring: Supports long-term asset integrity management and regulatory compliance through regular inspection of ageing repairs.

Accreditation & Validation

-

UKAS Accredited (The United Kingdom Accreditation Service) – Certified to ISO/IEC 17020:2012 for inspection body competence

-

Lloyd’s Register Validated – Recognised for non-destructive examination of composite wraps and repairs

-

Patent Pending – Reflecting the innovative nature and unique application of the technology

Specialist Operator Training

All inspections are conducted by technicians who have undergone ICR’s bespoke INSONO™ training programme. This course is only available to personnel who have previously been trained in the application of Technowrap™ repairs, ensuring inspection is carried out by experts who understand the nuances of both the material system and the inspection methodology.

Send us your enquiry

Please complete the form below, and a member of our team will be in touch as soon as possible. Alternatively, please send your enquiry directly to sales@icr-world.com